Special Use Of Fluidized-bed Jet Mill In High Hardness Materials

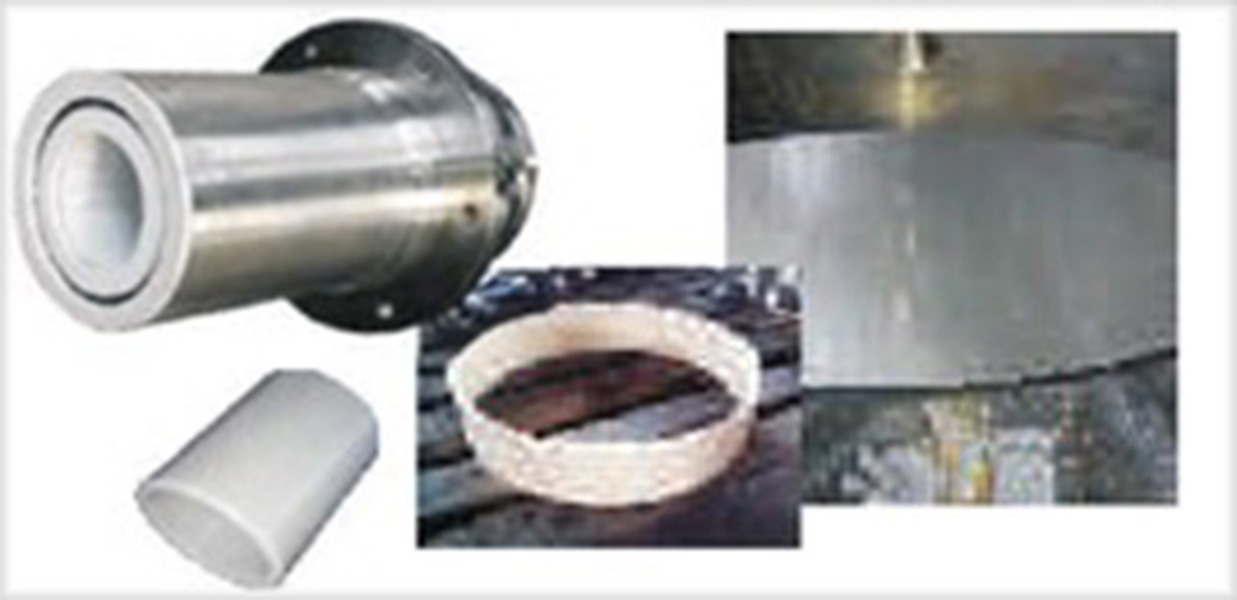

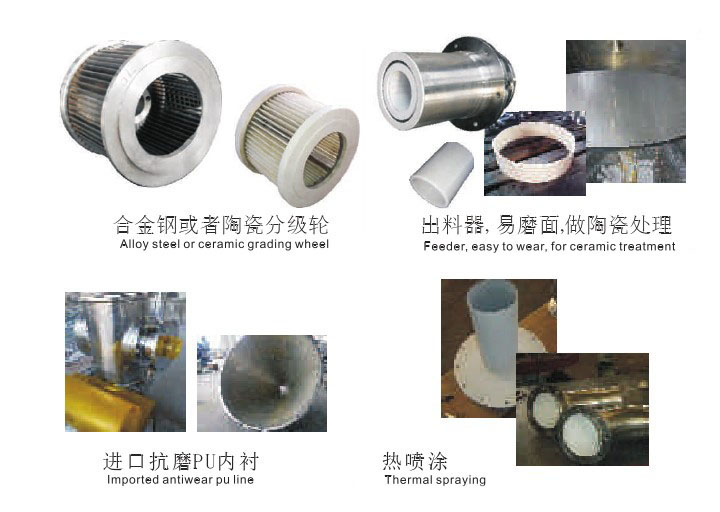

● Pasting PU or ceramics to cyclone separator and dust collector.

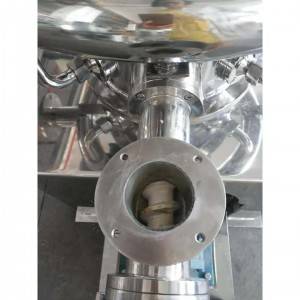

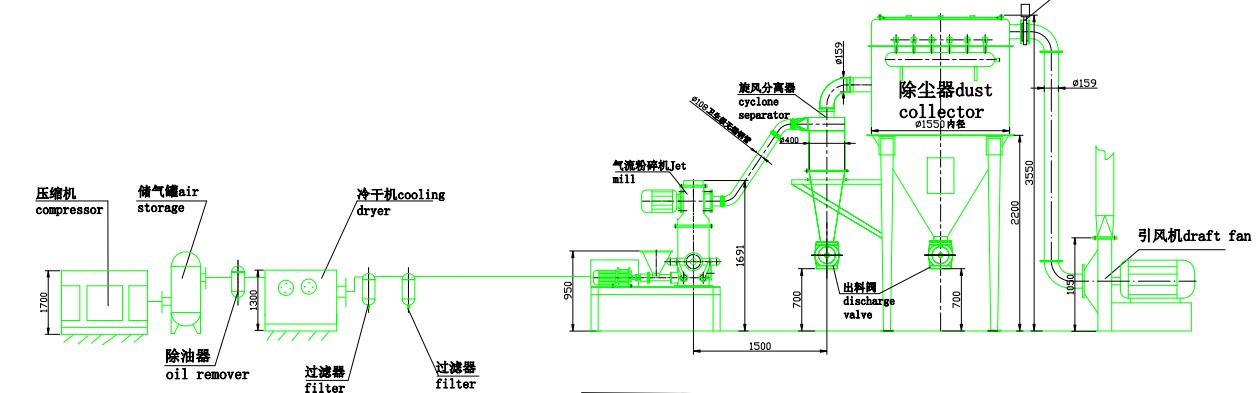

The jet mill grinding system consists jet mill, cyclone, bag filter and draft fan. Filtrated, desiccated and compressed air is ejected into the grinding chamber through air nozzle, the material is crushed each other at the joint of four high-pressure jet air flow and finally pulverized. Then, the material will be classified into different sizes under the centrifugal force and centripetal force. Qualified fine particles is collected by the cyclone and bag filter, while oversize particles will be returned to the grinding chamber for regrinding.

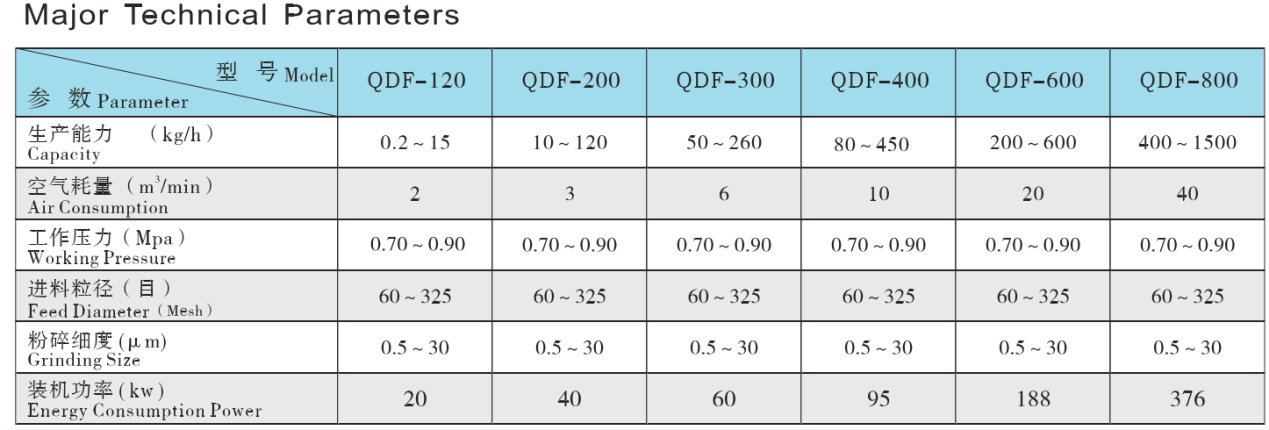

Notes: Compressed air consumption from 2 m3/min up to 40 m3/min. Production capacity depend on specific characters of your material, and can be tested in our test stations. Data of production capacity and product fineness in this sheet are just for your reference. Different materials have different characteristics, and then one model of jet mill will give different production performance for different material. Please contact me for tailored technical proposal or trials with your material.

1.Precision ceramic coatings, flexible anti-wear lining from material classification process to assure the purity of the products. Especially suitable for high hardness products,such as WC,SiC,SiN,SiO2 and so on.

2. No rise in temperature: The temperature will not increase as the materials are pulverized under the working conditions of pneumatic expansion and the temperature in the milling cavity is kept normal.

3.Endurance: Ceramic or SiO or Carborundum lining Applied to materials with Mohs Hardness Grade 5~9. the milling effect only involves the impact and collision among the grains rather than the collision with the wall . ensuring non-contact with metal throughout the grinding for high purity of the final.

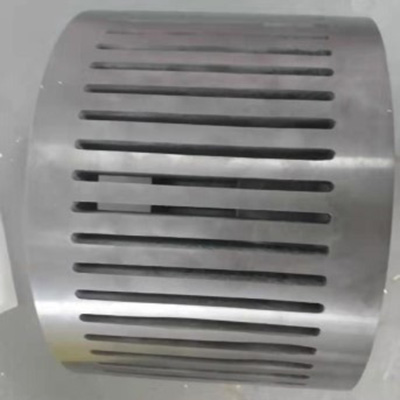

4. Speed of wheel is controlled by converter, particle size can be adjusted freely. The classifying wheel separates the material automatically with airflow to control efficiently the fineness of finished products.Ultrafine powder product is stable and reliable.

The flow chart is standard milling processing,and can be adjusted for customers.

PLC Control system

The system adopts intelligent touch screen control, easy operation and accurate control.

Plant Engineering

- Plant design

- Process monitoring, control and automation

- Software development and real time application programming

- Engineering

- Machinery manufacturing

Project Management

- Project planning

- Construction site supervision and management

- Installation and testing of instrumentation and control systems

- Machinery and plant commissioning

- Employee training

- Support throughout production

Project Definition

- Feasibility and concept study

- Cost and Profitability calculations

- Timescale and resource planning

- Turnkey solution, plant upgrade and modernization solutions

Project Design

- Knowledgable engineers

- Using the latest technologies

- Exploiting the knowledge gained from hundreds of applications across any industries

- Leverage expertise from our experienced engineers and partners