Professional China Jet Air Grinder Parts – Components For Jet Mil – Qiangdi

Professional China Jet Air Grinder Parts – Components For Jet Mil – Qiangdi Detail:

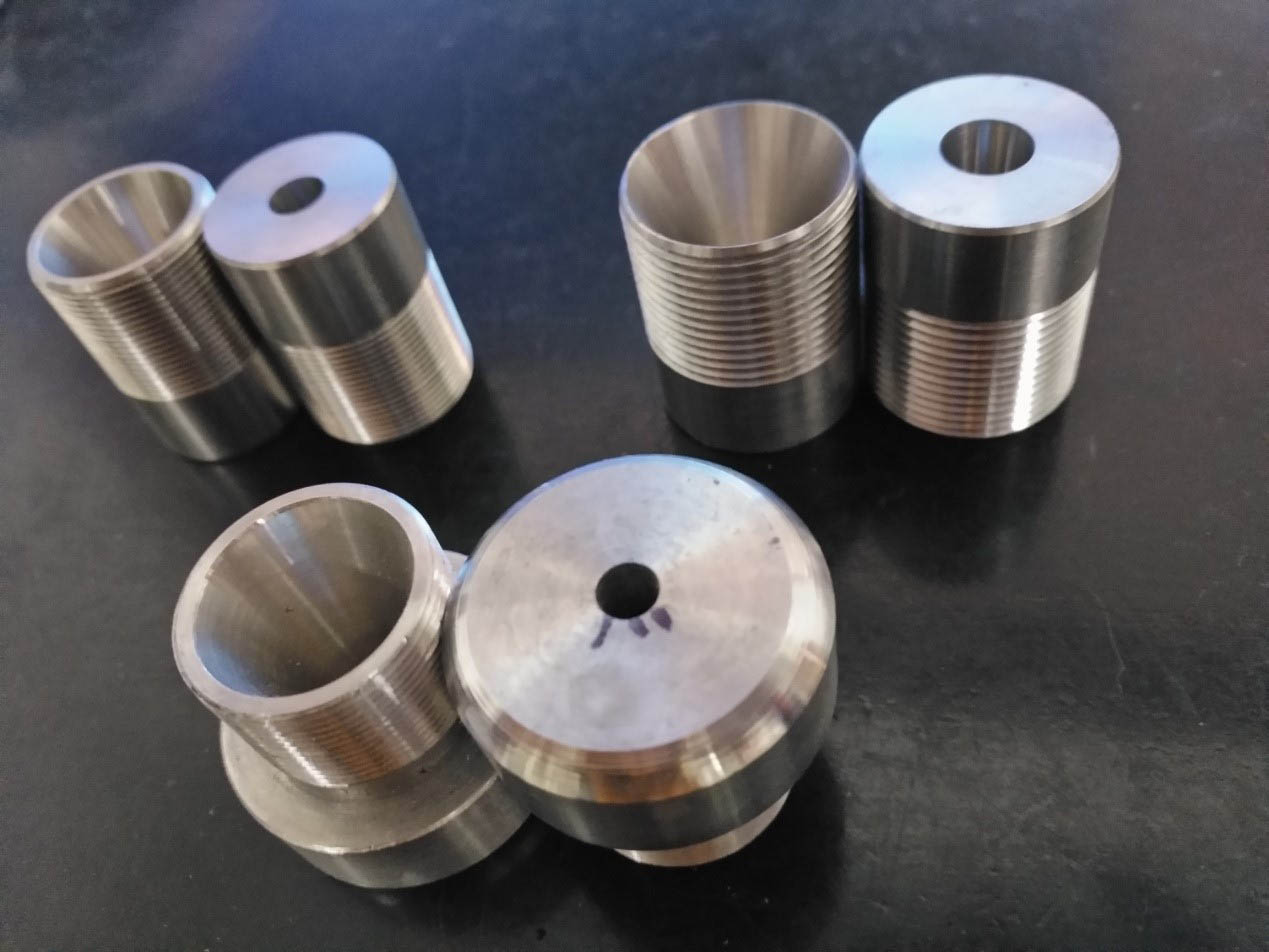

1.the bearing outside, prevent the material from entering inside, then jam.

2.valve and valve core are casting parts, no deformation after long term use.

3.CNC process ensures good precision.

Description

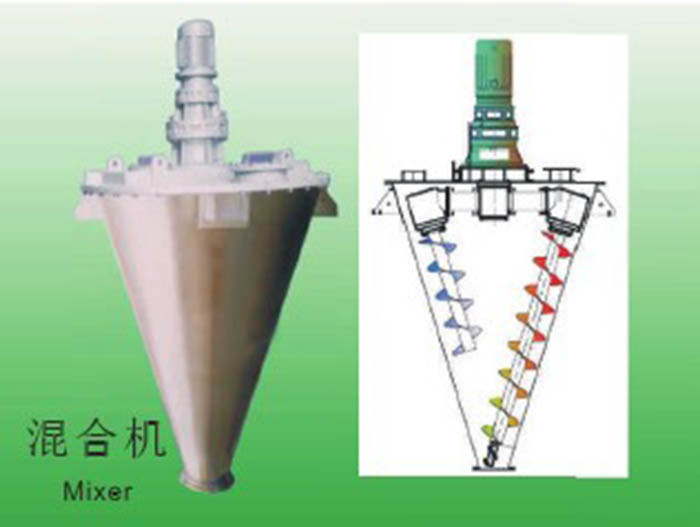

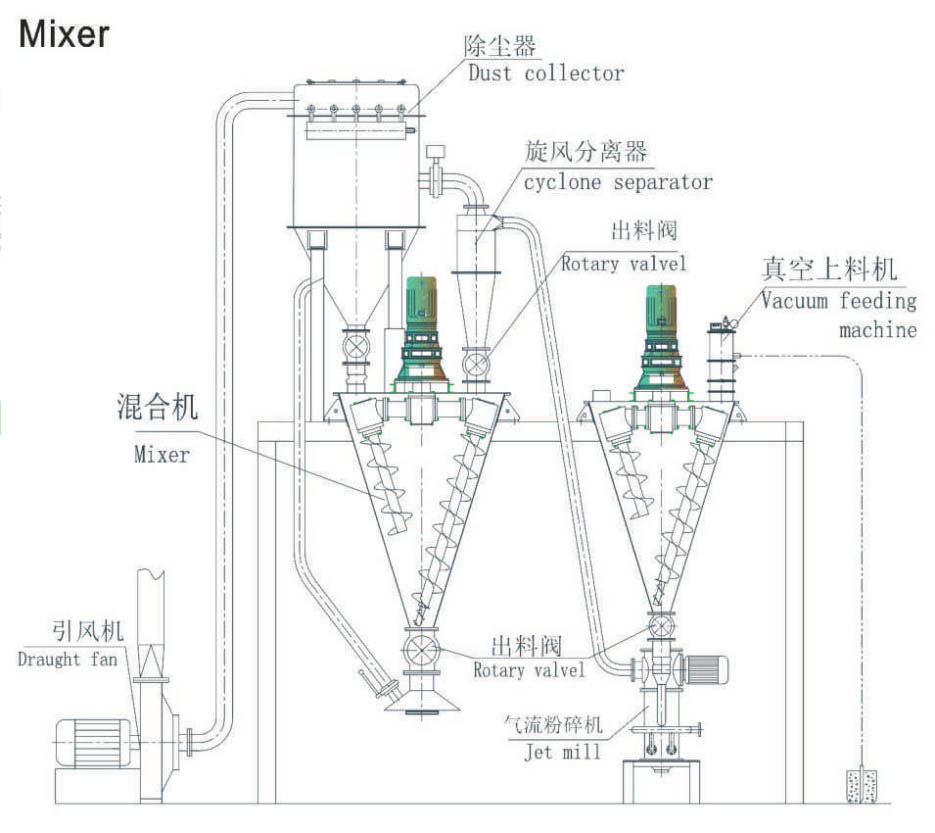

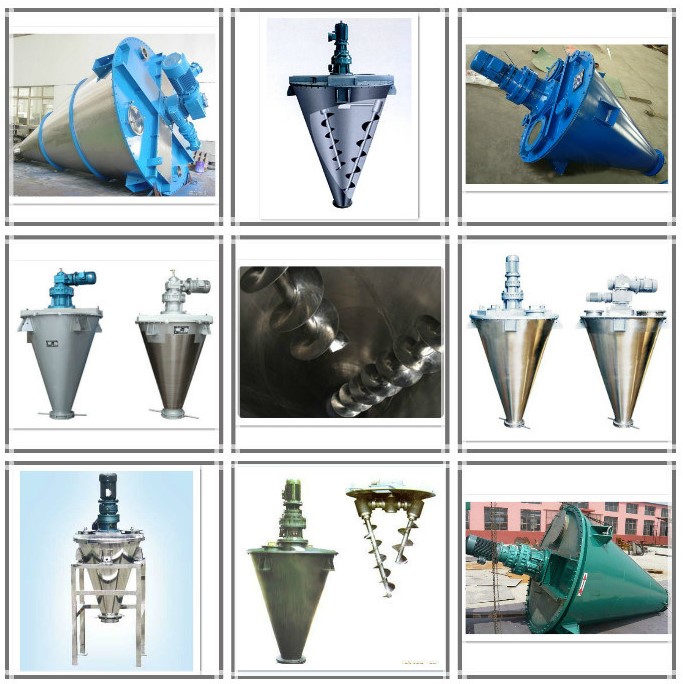

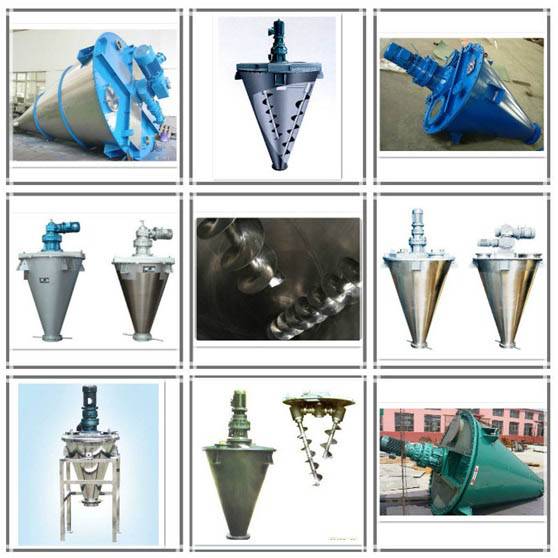

DSH double screw mixer integrates powder, granule and liquid mixing. The rotation of twin screw mixer is completed by a set of motors and cycloid reducers. With asymmetric mixing by two screws, the stirring range will be expanded and stirring speed will accelerate. The mixing machine is promoted by two asymmetric spirals of the rapid rotation, forming two non-symmetrical spiral columns that flow upward from the cylinder wall. Turning arm driven by spiral orbit, makes the spiral material of different level into the stud in the envelope, dislocation part of the material being promoted, the other part of the material being thrown screw, so as to achieve full circle bearing materials constantly updated. The two materials mentioned above are then rejoined to the concave cavity of the center, forming a downward flow of materials and supplementing the hole at the bottom, thus forming convective circulation.

Feature

1.Homogeneous mixing

2.Short mixing time 5-15 minutes

3.Clean discharge & no leftover

4.Central discharge valve:

Electronic, pneumatic, manual (optional)

Ball valve, flap valve, knife gate valve, butterfly valve (optional)

5.Main shaft seal:Stuffing seal and air purge seal

6.Drive:Siemens motor, cycloid or gear reducer

7.Limit/safety switch (optional)

8.Heating/cooling jacket optional)

Cone mixer application:

1.Applicable material proportion of the poor, the powder particles are relatively large materials;

2.Suitable for ceramic glaze mixing gentle process, the material particles do not pressure-fed or broken;

3.The heat-sensitive materials will not overheat;

4.In the powder - powder mixing process is very easy to add working conditions or providing a liquid to a plurality of spray outlet means;

5.The bottom valve of dislocation convenient material, since the bottom of the spiral no fixtures, so there is no pressure fed phenomenon

Working principle:

Horizontal double ribbon mixer consist of horizontal U-shaped tank, top cover with (or without) openings, single shaft equipped with double layers ribbon mixing agitator, transmission unit, support frame, sealing element, discharge structure and so on. Ribbon blades are always two layers. Outer layer ribbon make materials get together from two ends to center and inner layer ribbon make materials spread from center to two ends. Materials forms vortex during repeatedly movement and homogeneous mixing are achieved.

Performance & features:

1. Material: stainless steel 304 / 316L or mild steel Q235;

2. Surface treatment: paint (mild steel), polish/sandblasting (stainless steel);

3. Ribbon agitator: double layers & double directions;

4. Mixer tank: horizontal, U-shaped tank;

5. Shaft: horizontal, hollow, integral single shaft;

6. Mixing time: 5-15 minutes;

7. Working model: batch mixing;

8. Speed reducer: cycloid reducer;

9. Rotation speed: fixed speed;

10. Main shaft seal: (Teflon) stuffing seal or air purge seal;

11. Openings: feeding inlet, manhole, and inspection / connection port;

12. Discharge valve: pneumatic or manual flap discharge valve;

13. Working condition: NPT (normal pressure and temperature);

14. Not heavy duty: mixer can not be started with loading materials;

15. Power supply: 220V 50HZ single phase/ 380V 50HZ 3 phase;

16. Non ex-proof electronics (motor, electronic elements, control cabinet);

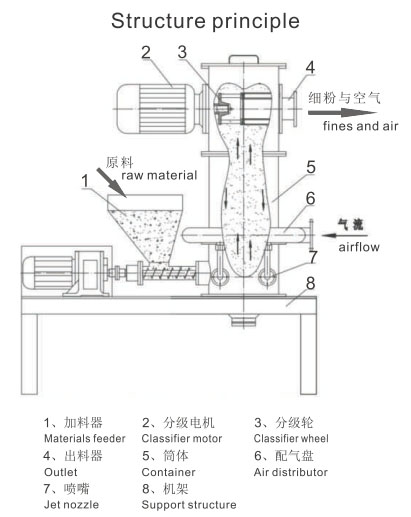

Jet Nozzle

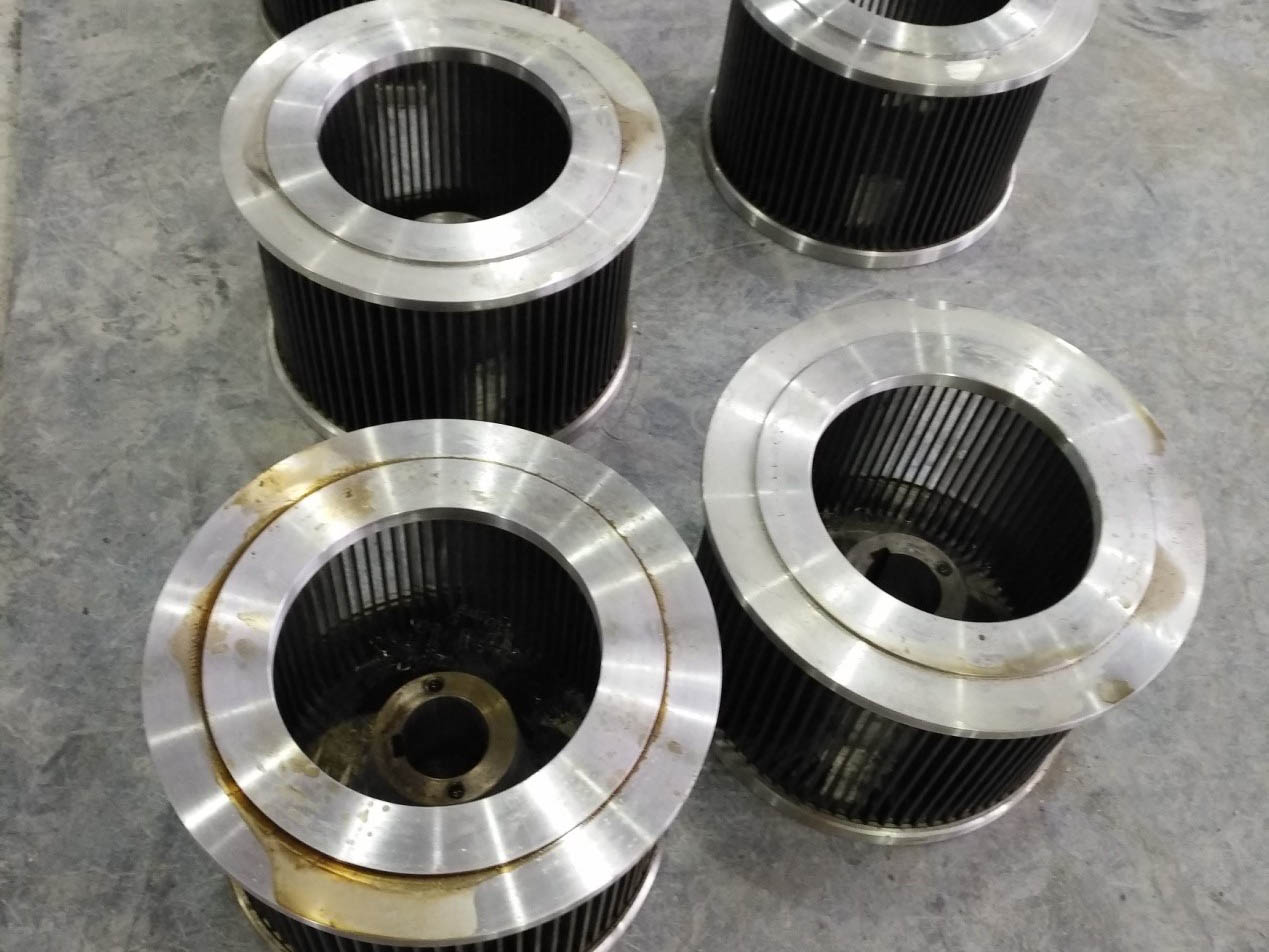

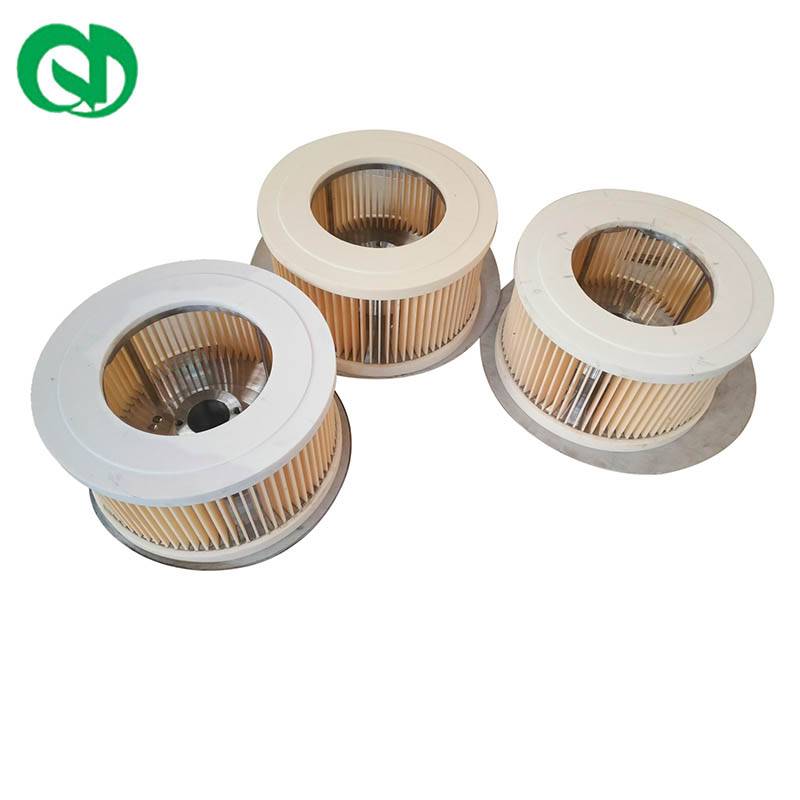

Classified Wheel

Product detail pictures:

Related Product Guide:

We have been convinced that with joint attempts, the business enterprise between us will bring us mutual benefits. We could guarantee you product or service good quality and aggressive value for Professional China Jet Air Grinder Parts – Components For Jet Mil – Qiangdi , The product will supply to all over the world, such as: Mexico, Bangladesh, Swansea, We are seeking the chances to meet all the friends from both at home and abroad for the win-win cooperation. We sincerely hope to have long-term cooperation with all of you on the bases of mutual benefit and common development.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.