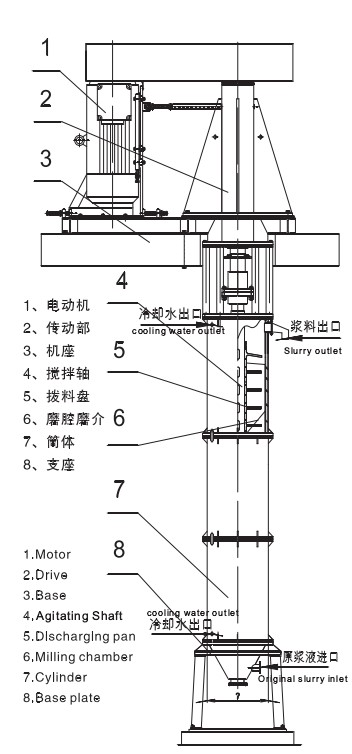

Professional China Crushing Mill - LSM Vertical Wet Stirring Mill – Qiangdi

Professional China Crushing Mill - LSM Vertical Wet Stirring Mill – Qiangdi Detail:

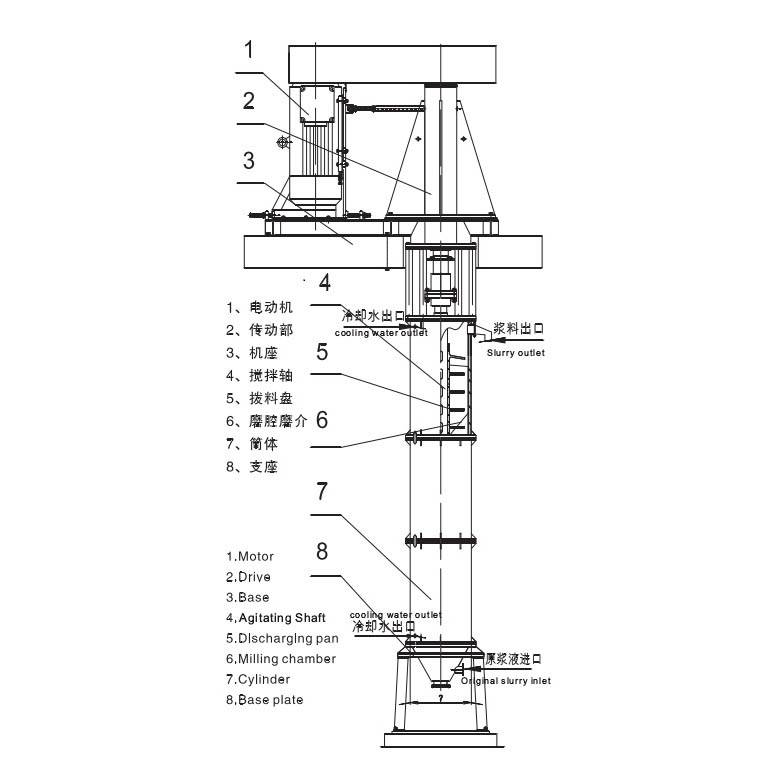

1 .LSM mixing mill absorbs the equipment characteristics of grinding, sanding, tower grinding and so on. It has the advantages of high efficiency, low noise, large processing capacity and convenient operation and maintenance.

2.when the feed size is 325 mesh, after two times of grinding can reach more than -2 Nm m95% (average particle size of 0.6 μm below).

3.you can superfine grinding, but also get excellent flow state pulp.

4. grinding cylinder grinding disc using wear-resistant materials and high hardness wear-resistant alloy materials, equipment, long service life.

5.the use of grinding media wear, particle size ratio of science, in the grinding process, no iron pollution, does not affect the product whiteness.

6.use a wet grinding mill can be continuous operation, independent of a product grinding, or can be repeated cycle feed to complete two or more products grinding.

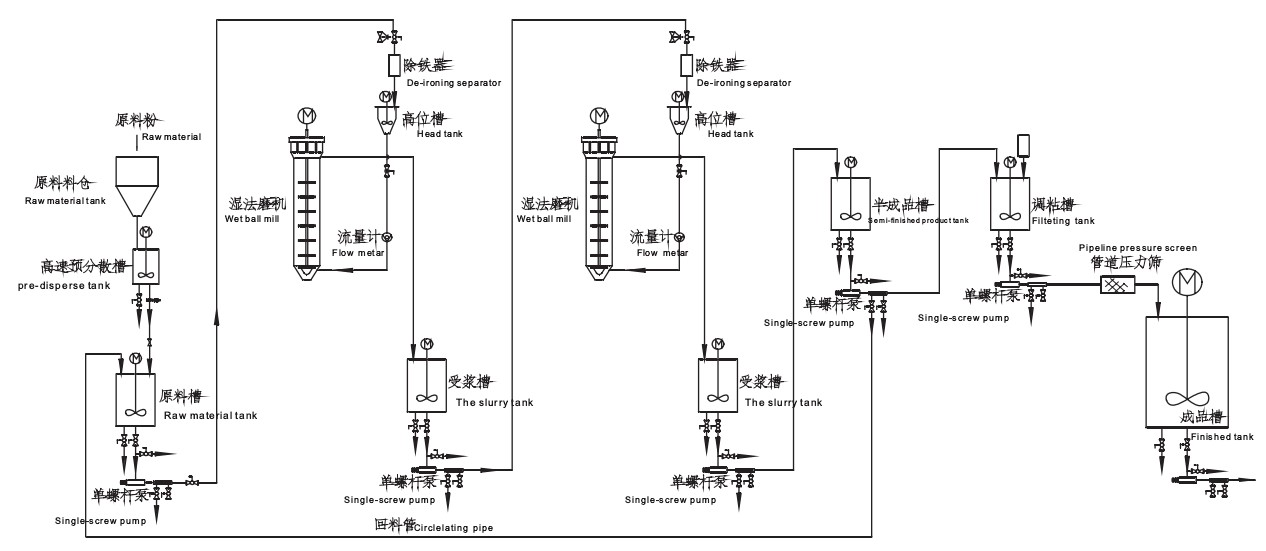

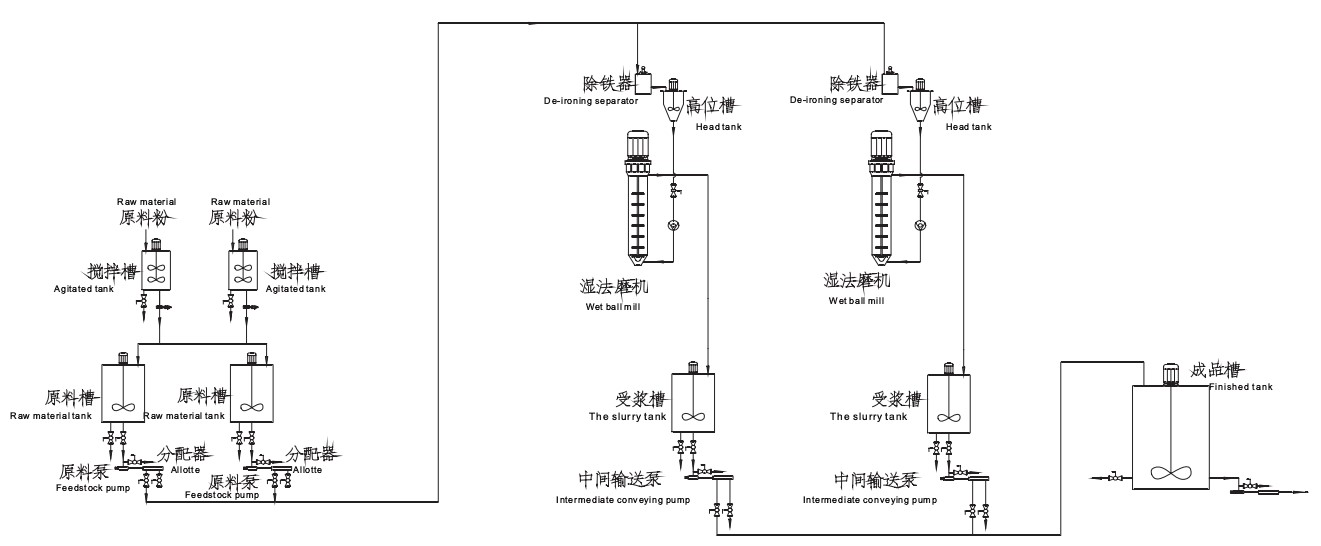

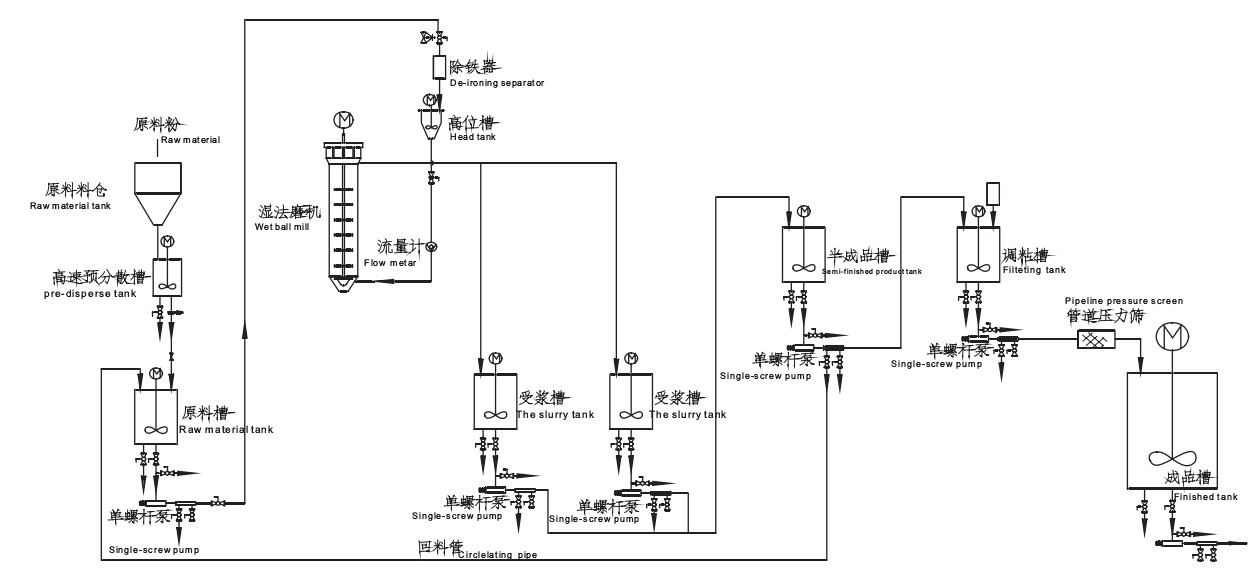

The following processes are for reference only and can be designed according to customer fineness and capacity requirements.

(1) One set Wet Ball mill flowchart

(2) Two sets in series flowchart

(3) Two sets in parallel flowchart

Product detail pictures:

Related Product Guide:

We normally think and practice corresponding on the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and also the living for Professional China Crushing Mill - LSM Vertical Wet Stirring Mill – Qiangdi , The product will supply to all over the world, such as: belarus, Japan, Cannes, To achieve reciprocal advantages, our company is widely boosting our tactics of globalization in terms of communication with overseas customers, fast delivery, the best quality and long-term cooperation. Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!