Massive Selection for Chemical/Oxide/Nonmetal Pulverizer - Jet Micron Grader For Sorting – Qiangdi

Massive Selection for Chemical/Oxide/Nonmetal Pulverizer - Jet Micron Grader For Sorting – Qiangdi Detail:

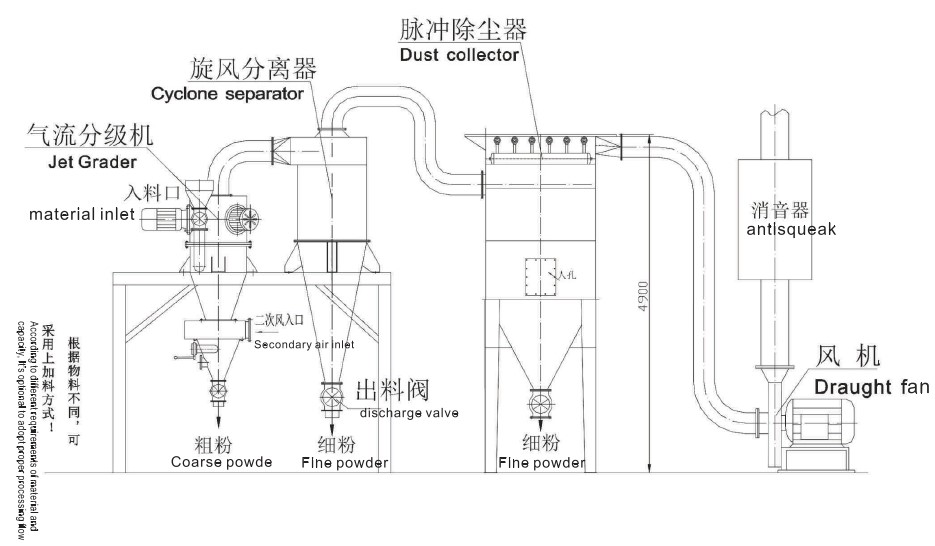

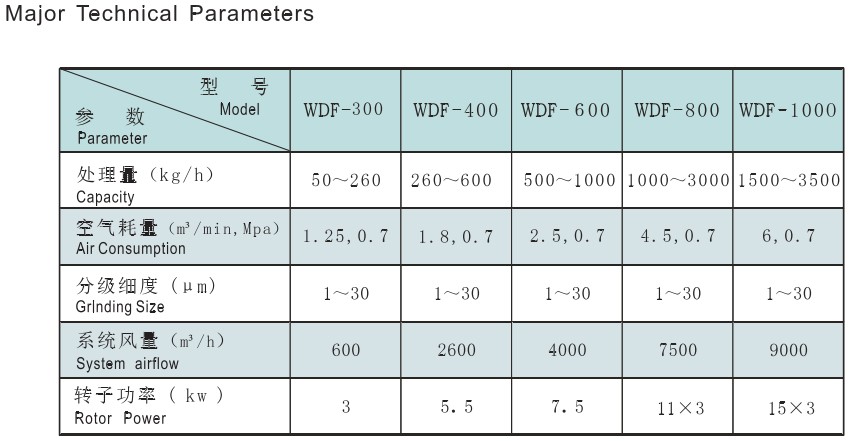

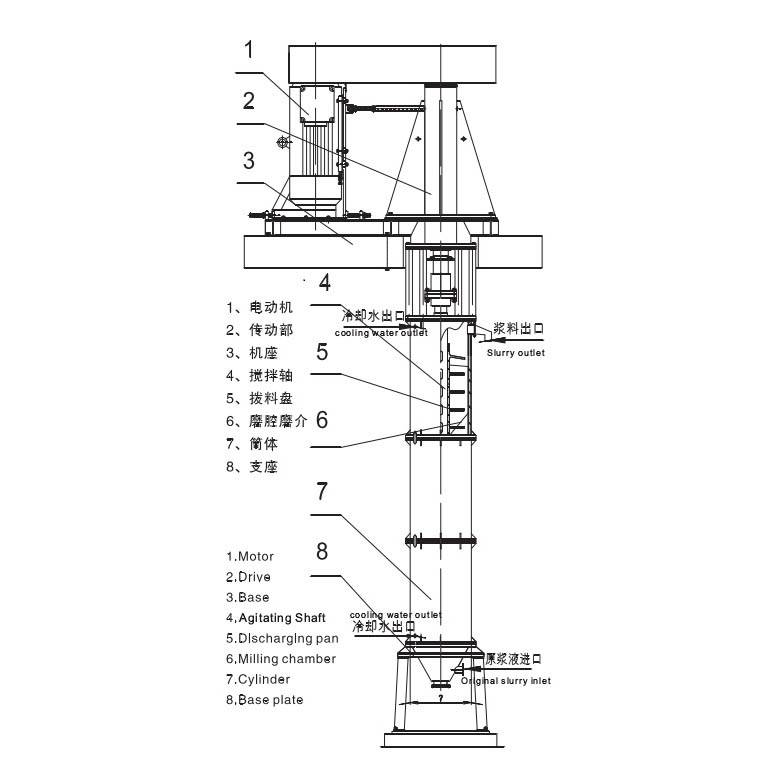

The turbine grader, as a forced centrifugal grader with secondary air entry and horizontal grading rotator is composed of grading rotator, guide vane rectifier and screw feeder. The materials are fed through the upper cartridge, and the grains will be sieved and well distributed by the incoming air,which brings the grain to the grading zone. The centrifugal force produced by the fast rotation of grading rotator together with the centripetal force produced by the pneumatic adhesion both act on the grading grains. When the centrifugal force on the grain is greater than the centripetal force, the coarser grains above the grading range will be swirled down along the container wall. The secondary air will be rectified to uniform cyclone through the guide vane and separate the thinner grains from the coarserones. The separated coarser grains will be blown out from the discharge port. The thinner grains will come to cyclone separator and collector, whereas the purified air will be vented outside from the draft.

1 .Compatible with a variety of dry type powder mill machinery (jet mill, ball mill,Raymond mill) to form a closed circuit.

2. Applied to the fine classifying of dry micron-grade products like ball, flake, needle particles and particles of different density.

3. The latest design classification rotor is used, which is a significant improvement in classifying particle size compared to former generation product, with advantages like high-precision grading and adjustable particle size and very convenient varieties replacement. vertical grading turbine device with low rotating speed, resistance to wear and low system power.

4. controlling system is automatic, running condition is displayed real time, operation is very easy.

5. system is running under negative pressure, dust emissions is less than 40mg/m, equipment noise is no higher than 60db(A)by adopting noise damping measurement.

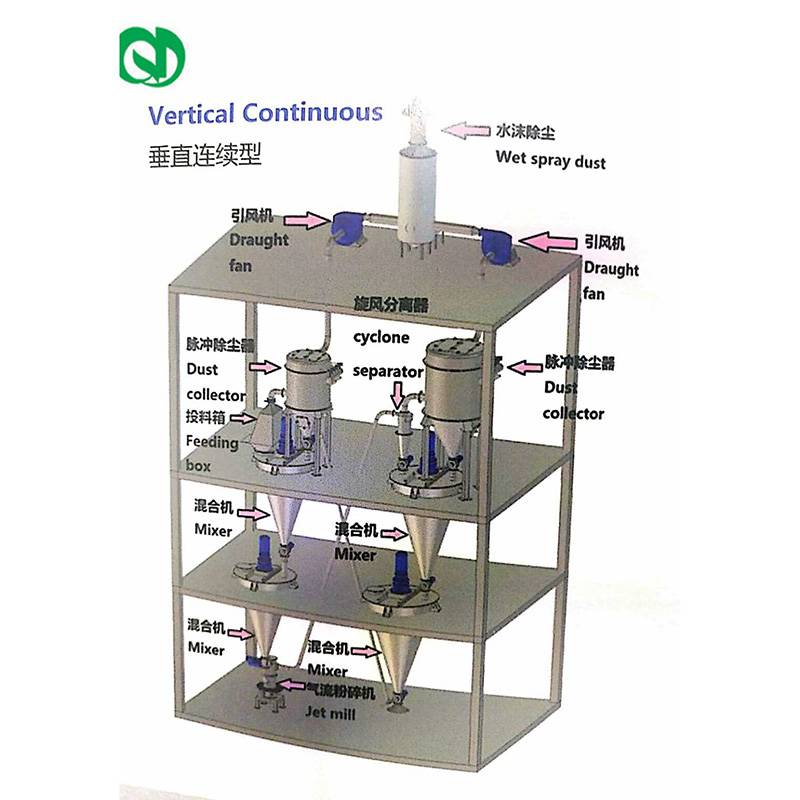

Design different process flow according to material and capacity

Product detail pictures:

Related Product Guide:

We always get the job done to be a tangible staff to ensure that we can easily offer you the best high-quality and the greatest value for Massive Selection for Chemical/Oxide/Nonmetal Pulverizer - Jet Micron Grader For Sorting – Qiangdi , The product will supply to all over the world, such as: Norway, Slovakia, Russia, We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The products to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they're created scientifically of purely raw supplies. It readily available in a variety of designs and specifications for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.