Welcome to our websites!

Featured

-

Reasonable price for Powerfeed Jet Mill - Battery Industry And Other Chemical Material Use Fluidized-bed Jet Mill – Qiangdi

Fluidized bed pneumatic mill is the equipment used to crush dry materials to superfine powder, with the basic structure as follows: The Product is a fluidized bed pulverizer with the compression air as the crushing medium. The mill body is divided into 3 sections, namely the crushing area, transmission area and the grading area. The Grading Area is provided with the grading wheel, and the speed can be adjusted by the converter. The crushing room is composed of the crushing nozzle, feeder, ... -

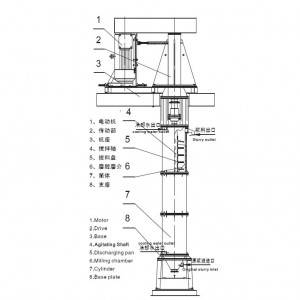

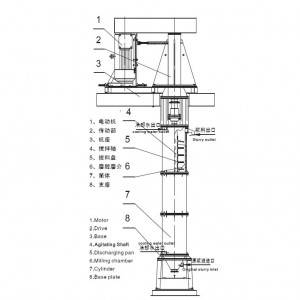

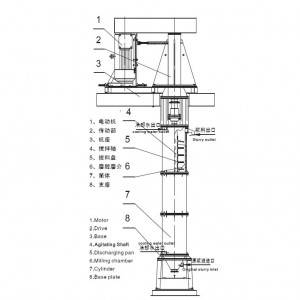

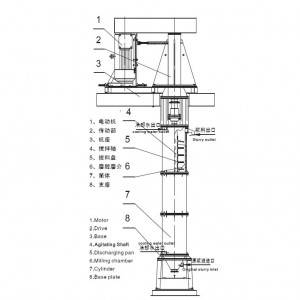

Renewable Design for Spice Mill Grinder For Powder – LSM Vertical Wet Stirring Mill – Qiangdi

1 .LSM mixing mill absorbs the equipment characteristics of grinding, sanding, tower grinding and so on. It has the advantages of high efficiency, low noise, large processing capacity and convenient operation and maintenance. 2.when the feed size is 325 mesh, after two times of grinding can reach more than -2 Nm m95% (average particle size of 0.6 μm below). 3.you can superfine grinding, but also get excellent flow state pulp. 4. grinding cylinder gri... -

New Fashion Design for Air Classifying Mill - LSM Vertical Wet Stirring Mill – Qiangdi

1 .LSM mixing mill absorbs the equipment characteristics of grinding, sanding, tower grinding and so on. It has the advantages of high efficiency, low noise, large processing capacity and convenient operation and maintenance. 2.when the feed size is 325 mesh, after two times of grinding can reach more than -2 Nm m95% (average particle size of 0.6 μm below). 3.you can superfine grinding, but also get excellent flow state pulp. 4. grinding cylinder gri... -

100% Original Milling And Grinding Machines - LSM Vertical Wet Stirring Mill – Qiangdi

1 .LSM mixing mill absorbs the equipment characteristics of grinding, sanding, tower grinding and so on. It has the advantages of high efficiency, low noise, large processing capacity and convenient operation and maintenance. 2.when the feed size is 325 mesh, after two times of grinding can reach more than -2 Nm m95% (average particle size of 0.6 μm below). 3.you can superfine grinding, but also get excellent flow state pulp. 4. grinding cylinder gri... -

Good quality Jet Milling Equipment - Popular type Fluidized-bed Jet Mill – Qiangdi

We are manufacturer for powder processing machines. More important, we provide tailored design of machine, of engineering, of control system to meet our clients’ production requirements. We are a project supplier. We provide solution for powder processing. The Fluidized-bed Jet mill is actually such a device that using the high speed air flow to perform the dry-type superfine pulverizing. Driven by compressed air, raw material is accelerated to the crossing of four nozzles to be i... -

Fixed Competitive Price Abrasion-Proof Material Jet Mill - GMP FDA Fluidized-bed Jet Mill – Qiangdi

Jet mill structure drawing- under the action of centrifugal force of classifier wheel and centripetal force of draft fan,material come into being fluid-bed in the inner of jet mill.thereby getting different fineness powder . The Product is a fluidized bed pulverizer with the compression air as the crushing medium. The mill body is divided into 3 sections, namely the crushing area, transmission area and the grading area. The Grading Area is provided with the grading wheel, and the speed ca... -

Factory For Jet Mill Process - GMP FDA Fluidized-bed Jet Mill – Qiangdi

Jet mill structure drawing- under the action of centrifugal force of classifier wheel and centripetal force of draft fan,material come into being fluid-bed in the inner of jet mill.thereby getting different fineness powder . The Product is a fluidized bed pulverizer with the compression air as the crushing medium. The mill body is divided into 3 sections, namely the crushing area, transmission area and the grading area. The Grading Area is provided with the grading wheel, and the speed ca... -

Factory directly supply Laboratory Spiral Jet Mill - Battery Industry And Other Chemical Material Use Fluidized-bed Jet Mill – Qiangdi

Fluidized bed pneumatic mill is the equipment used to crush dry materials to superfine powder, with the basic structure as follows: The Product is a fluidized bed pulverizer with the compression air as the crushing medium. The mill body is divided into 3 sections, namely the crushing area, transmission area and the grading area. The Grading Area is provided with the grading wheel, and the speed can be adjusted by the converter. The crushing room is composed of the crushing nozzle, feeder, ... -

Factory wholesale Cosmetics Customized Jet Mill - WP-WDG System–Apply To Agrochemical Field – Qiangdi

WP part First,Raw material feed from the feeder –the material transfer to the first 3 m3mixer for premixing, and dust collector will collect dust during the feeding process, then mixed material enter into QDF-600 jet mill for milling, the output particle size can be adjusted by adjusting different rotating speed of the classifier wheel,. After milling, material will transfer to the cyclone and dust collector on the top of the first 4m3 mixer through centripetal force of draft fan, then ... -

Factory Price Rotary Classifier Mill - LSM Vertical Wet Stirring Mill – Qiangdi

1 .LSM mixing mill absorbs the equipment characteristics of grinding, sanding, tower grinding and so on. It has the advantages of high efficiency, low noise, large processing capacity and convenient operation and maintenance. 2.when the feed size is 325 mesh, after two times of grinding can reach more than -2 Nm m95% (average particle size of 0.6 μm below). 3.you can superfine grinding, but also get excellent flow state pulp. 4. grinding cylinder gri... -

Factory making Jet Vertical Mill Price - Lab-use Disc-type jet mill QDB-50 QDB-100 QDB-150 – Qiangdi

Jet Mill used in Lab, whose principle is : Driven by compressed air through feeding injectors,raw material is accelerated to ultrasonic speed and injected into milling chamber in tangential direction, collided and grinded into particle. The particle size can be controlled by adjusting longitudinal depth, milling pressure and material feeding speed. Disc type Jet Mill do good performance to gummy materials. 1.Small batch production demand of lab,using the desktop design... -

PriceList for Air Classifier - Jet Micron Grader For Sorting – Qiangdi

The turbine grader, as a forced centrifugal grader with secondary air entry and horizontal grading rotator is composed of grading rotator, guide vane rectifier and screw feeder. The materials are fed through the upper cartridge, and the grains will be sieved and well distributed by the incoming air,which brings the grain to the grading zone. The centrifugal force produced by the fast rotation of grading rotator together with the centripetal force produced by the pneumatic adhesion both...