Welcome to our websites!

Featured

-

China wholesale Air Jet Mill Mechanism - Battery Industry And Other Chemical Material Use Fluidized-bed Jet Mill – Qiangdi

Fluidized bed pneumatic mill is the equipment used to crush dry materials to superfine powder, with the basic structure as follows: The Product is a fluidized bed pulverizer with the compression air as the crushing medium. The mill body is divided into 3 sections, namely the crushing area, transmission area and the grading area. The Grading Area is provided with the grading wheel, and the speed can be adjusted by the converter. The crushing room is composed of the crushing nozzle, feeder, ... -

Special Price for Gmp/Fda Standard Jet Milling - Popular type Fluidized-bed Jet Mill – Qiangdi

We are manufacturer for powder processing machines. More important, we provide tailored design of machine, of engineering, of control system to meet our clients’ production requirements. We are a project supplier. We provide solution for powder processing. The Fluidized-bed Jet mill is actually such a device that using the high speed air flow to perform the dry-type superfine pulverizing. Driven by compressed air, raw material is accelerated to the crossing of four nozzles to be i... -

2021 High quality Micro Powder Grinding Mill - Jet Micron Grader For Sorting – Qiangdi

The turbine grader, as a forced centrifugal grader with secondary air entry and horizontal grading rotator is composed of grading rotator, guide vane rectifier and screw feeder. The materials are fed through the upper cartridge, and the grains will be sieved and well distributed by the incoming air,which brings the grain to the grading zone. The centrifugal force produced by the fast rotation of grading rotator together with the centripetal force produced by the pneumatic adhesion both... -

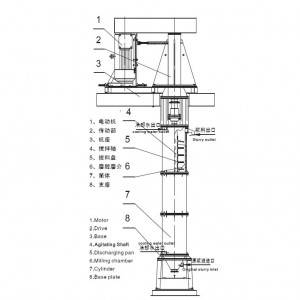

Hot sale Dry Mill Grinder - LSM Vertical Wet Stirring Mill – Qiangdi

1 .LSM mixing mill absorbs the equipment characteristics of grinding, sanding, tower grinding and so on. It has the advantages of high efficiency, low noise, large processing capacity and convenient operation and maintenance. 2.when the feed size is 325 mesh, after two times of grinding can reach more than -2 Nm m95% (average particle size of 0.6 μm below). 3.you can superfine grinding, but also get excellent flow state pulp. 4. grinding cylinder gri... -

Best Price for Air Jet Mill Fluidized Bed - Special Use Of Fluidized-bed Jet Mill In High Hardness Materials – Qiangdi

Use special material in parts of contact products to satisfy different hardness products’ grinding requirement. ● Ceramic or SiO or Carborundum classifier wheel to fit for different hardness products whose hardness is higher than steel. ● Pasting ceramic sheet on the inner wall of Jet mill. ● Pasting PU or ceramics to cyclone separator and dust collector. The jet mill grinding system consists jet mill, cyclone, bag filter and draft fan. Filtrated, desiccated and compressed air is ejected i... -

Professional China Jet Air Grinder Parts – Components For Jet Mil – Qiangdi

1.the bearing outside, prevent the material from entering inside, then jam. 2.valve and valve core are casting parts, no deformation after long term use. 3.CNC process ensures good precision. Description DSH double screw mixer integrates powder, granule and liquid mixing. The rotation of twin screw mixer is completed by a set of motors and cycloid reducers. With asymmetric mixing by two screws, the stirring range will be expanded and stirring speed will accelerate. The mixing ma... -

Europe style for High Hardness Material Jet Mill - Special Use Of Fluidized-bed Jet Mill In High Hardness Materials – Qiangdi

Use special material in parts of contact products to satisfy different hardness products’ grinding requirement. ● Ceramic or SiO or Carborundum classifier wheel to fit for different hardness products whose hardness is higher than steel. ● Pasting ceramic sheet on the inner wall of Jet mill. ● Pasting PU or ceramics to cyclone separator and dust collector. The jet mill grinding system consists jet mill, cyclone, bag filter and draft fan. Filtrated, desiccated and compressed air is ejected i... -

Reliable Supplier Air Jet Mill With Classifier - Battery Industry And Other Chemical Material Use Fluidized-bed Jet Mill – Qiangdi

Fluidized bed pneumatic mill is the equipment used to crush dry materials to superfine powder, with the basic structure as follows: The Product is a fluidized bed pulverizer with the compression air as the crushing medium. The mill body is divided into 3 sections, namely the crushing area, transmission area and the grading area. The Grading Area is provided with the grading wheel, and the speed can be adjusted by the converter. The crushing room is composed of the crushing nozzle, feeder, ... -

8 Year Exporter Jet Mills Powder Grinding - QDF-400 WP Continuous Production System Of Jet Mill For 400kg – Qiangdi

The Most popular WP line in Pakistan-QDF-400 continuous production system as below Flow diagram and photo First,Raw material feed from the feeder –the material transfer to the first 3 m3mixer for premixing, and dust collector will collect dust during the feeding process, then the 3m3 hopper store mixed material,then enter into jet mill for milling, the output particle size can be adjusted by adjusting different rotating speed of the classifier wheel,. After milling, material will ... -

Professional China Jet Air Grinder Parts – Components For Jet Mil – Qiangdi

1.the bearing outside, prevent the material from entering inside, then jam. 2.valve and valve core are casting parts, no deformation after long term use. 3.CNC process ensures good precision. Description DSH double screw mixer integrates powder, granule and liquid mixing. The rotation of twin screw mixer is completed by a set of motors and cycloid reducers. With asymmetric mixing by two screws, the stirring range will be expanded and stirring speed will accelerate. The mixing ma... -

Quality Inspection for Sorting Machine - Jet Micron Grader For Sorting – Qiangdi

The turbine grader, as a forced centrifugal grader with secondary air entry and horizontal grading rotator is composed of grading rotator, guide vane rectifier and screw feeder. The materials are fed through the upper cartridge, and the grains will be sieved and well distributed by the incoming air,which brings the grain to the grading zone. The centrifugal force produced by the fast rotation of grading rotator together with the centripetal force produced by the pneumatic adhesion both... -

China Factory for Pharmaceutical Machinery - Jet Micron Grader For Sorting – Qiangdi

The turbine grader, as a forced centrifugal grader with secondary air entry and horizontal grading rotator is composed of grading rotator, guide vane rectifier and screw feeder. The materials are fed through the upper cartridge, and the grains will be sieved and well distributed by the incoming air,which brings the grain to the grading zone. The centrifugal force produced by the fast rotation of grading rotator together with the centripetal force produced by the pneumatic adhesion both...