Factory source Used Jet Milling Machine - Lab-use Fluidized-bed Jet Mill For 1-10kg Capacity – Qiangdi

Factory source Used Jet Milling Machine - Lab-use Fluidized-bed Jet Mill For 1-10kg Capacity – Qiangdi Detail:

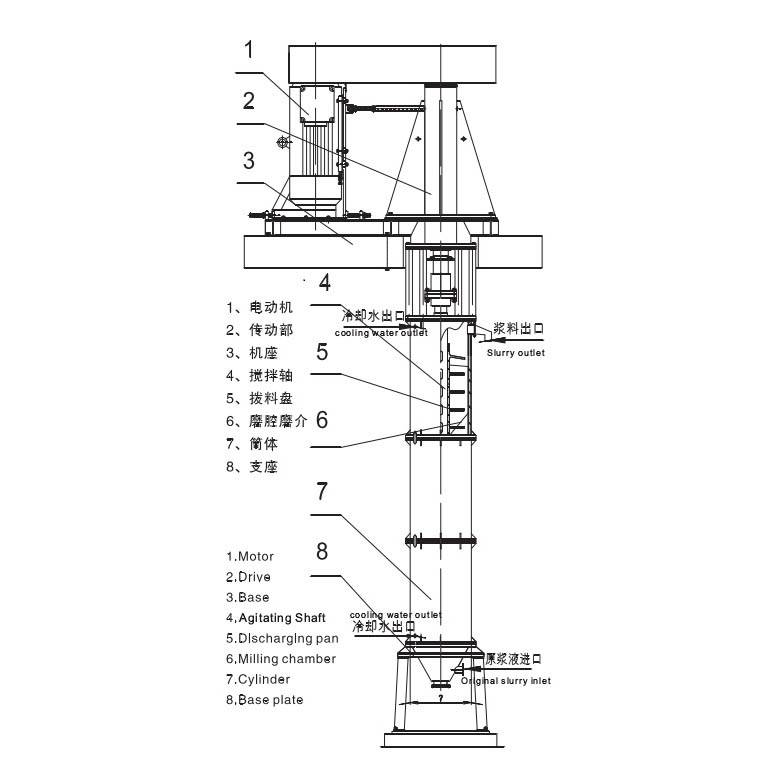

Jet mill main machine structure drawing

Jet Mill used in Lab, whose principle is based on the principle of the fluidized bed Jet Mill is such a device as using the high-speed airflow to perform the dry-type superfine pulverizing. The grains are accelerated in the high-speed airflow.

The materials will be ground by being accelerated impacted and collided repeatedly in the midst of high-speed airflow. The pulverized materials are separated by the grading wheel and the required particles are separatedthen collected by Cyclone Separator and Collector, The coarser materials are sent back to the milling chamber for further pulverizing until they reach the required size .

1.Mainly for Low capacity demand, 0. 5-10kg/h, fit to be used in Lab.

2.The unit is designed as a compact internal structure to perform closed circuit milling.

3.No temperature rise, low unit noise, no impurity, low waste during milling.

4.Small dimension, compact shape, fit to be used in Lab. The system adopts intelligent touch screen control, easy operation and accurate control.

5.With good air proof, ensure clean environment. Convenient operation and maintenance, automatic equipment operation.

6. Wide grading scope: the crushing fineness of the material can be regulated through adjusting the rotation speed of the grading wheels and the system. Generally, it can reach d =2~15μm

7. Low energy consumption:It can save 30%~40% energy compared with other air pneumatic pulverizers.

8. Low wear: Because the crushing effect is caused by the impact and collision of particles, the high-speed particles seldom hit the wall. It is applicable to crushing the material below Moh’s Scale 9.

APPLICATON SCOPE

It is widely applied to superfine pulverizing for nonmetallic ores, chemical metallurgy, western medicines, traditional Chinese medicine, agricultural chemical and ceramics, fit to be used in Lab.

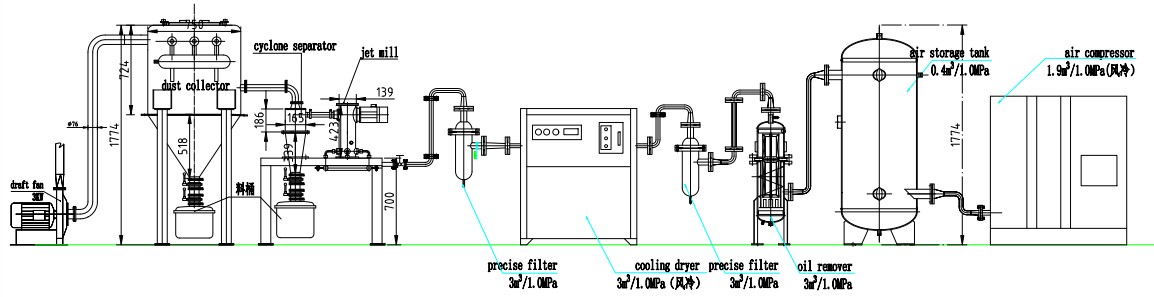

Flow chart of Fluidized-bed Jet Mill

The flow chart is standard milling processing,and can be adjusted for customers.

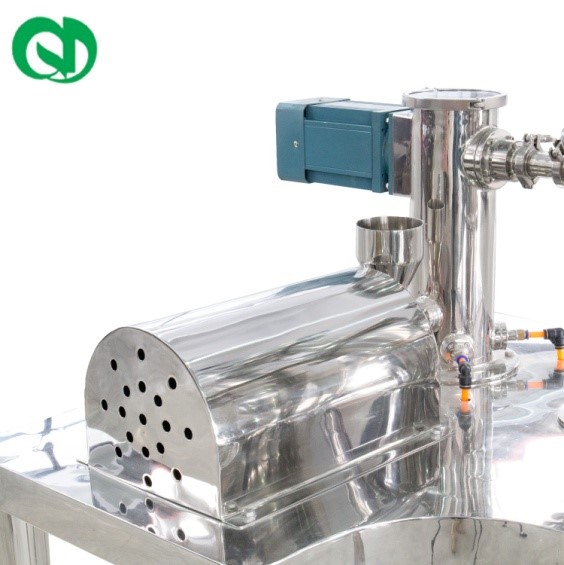

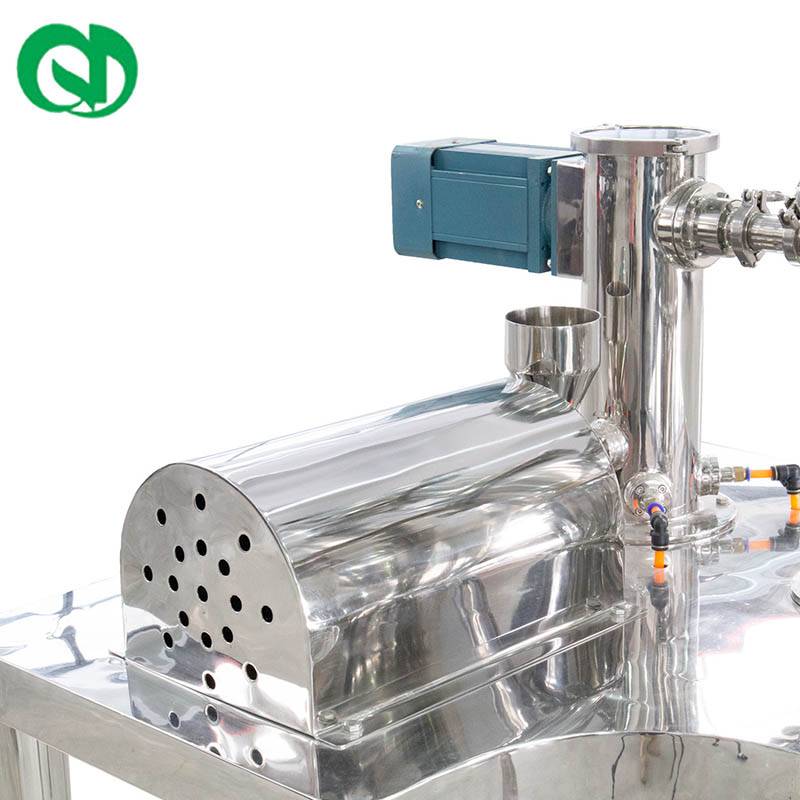

Machine Details design

1. Structure is simple,with washing hole,easy to clean

2. Motor with cap to avoid powder intaking

3. Compact structure:occupation of land is small

Pre-service:

Act as a good adviser and assistant of clients to enable them get rich and generous returns on their investments.

1. Introduce the product to the customer in detail, answer the question raised by customer carefully;

2. Make plans for choice according to the needs and special requirements of users in different sectors;

3. Sample testing support.

4. View our Factory.

Quality Assurance

1. Strictly conforming to ISO9001-2000 quality management system;

2. Strict control from purchasing inspection, process inspection to final proofing;

3. Established several QC departments to execute quality control regulations;

4. Detailed quality control examples:

(1) Complete files for quality control and quality feedback;

(2) Strict inspection for the components of our grinding mills, to assure products free of damage and avoid

rust-eaten and paint peeling off later on.

(3) Only qualified components will be assembled and total equipment must be inspected completely before sale.

Tech Support

Upon sales confirmation, we will offer the following technical services:

1. Design for your production line flow and equipment layout, free of charge;

2. Provide foundation drawings of customer- ordered grinding mills and drawings of related parts, etc;

3. Technical parameters of peripheral equipment will be supplied;

4. Free technical suggestions on adjusting of equipment layout and application;

5. Equipment upgrading (customers need to pay the cost);

After Sale Service

1. We will send our technician to the site for guiding equipment installation and commissioning.

2. During the installation and commissioning, we offer operator training service.

3. The quality assurance date is one year after commissioning. And after that, we will collect the cost if provide repairing for your equipment.

4. Maintenance for equipment failure caused by improper handling (appropriate cost will be collected).

5. We offer the components with favorable price and perdurable maintenance.

6. If equipment repairing is needed after quality assurance date is expired, we will collect maintenance cost.

Product detail pictures:

Related Product Guide:

We offer fantastic energy in high quality and enhancement,merchandising,profits and promoting and procedure for Factory source Used Jet Milling Machine - Lab-use Fluidized-bed Jet Mill For 1-10kg Capacity – Qiangdi , The product will supply to all over the world, such as: Korea, New Delhi, Sao Paulo, Due to the stability of our items, timely supply and our sincere service, we are able to sell our merchandise not only over the domestic market, but also exported to countries and regions, including the Middle East, Asia, Europe and other countries and regions. At the same time, we also undertake OEM and ODM orders. We will do our best to serve your company, and establish a successful and friendly cooperation with you.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!