Factory Promotional Laboratory Jet Mill Micronizer - Jet Mill WP System–Apply to Agrochemical Field – Qiangdi

Factory Promotional Laboratory Jet Mill Micronizer - Jet Mill WP System–Apply to Agrochemical Field – Qiangdi Detail:

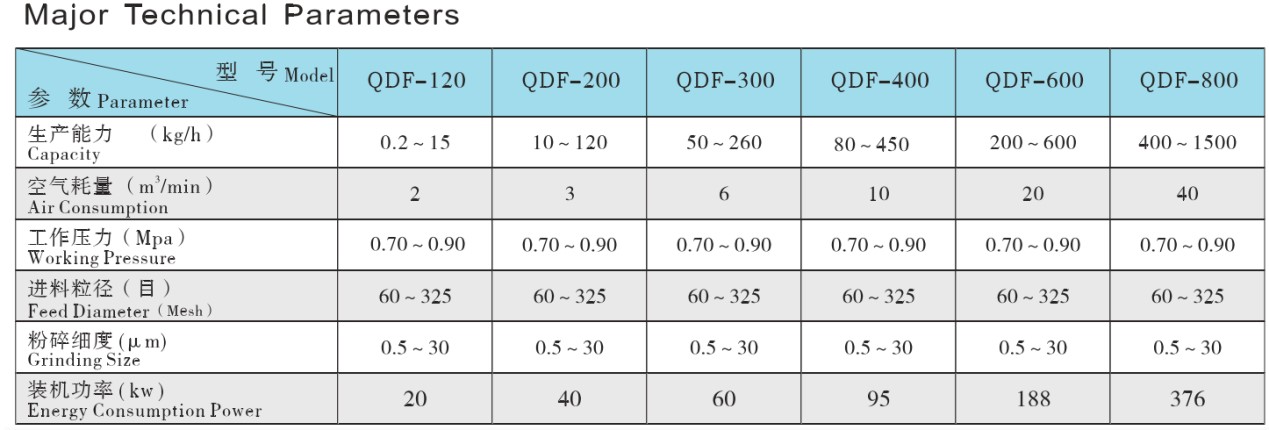

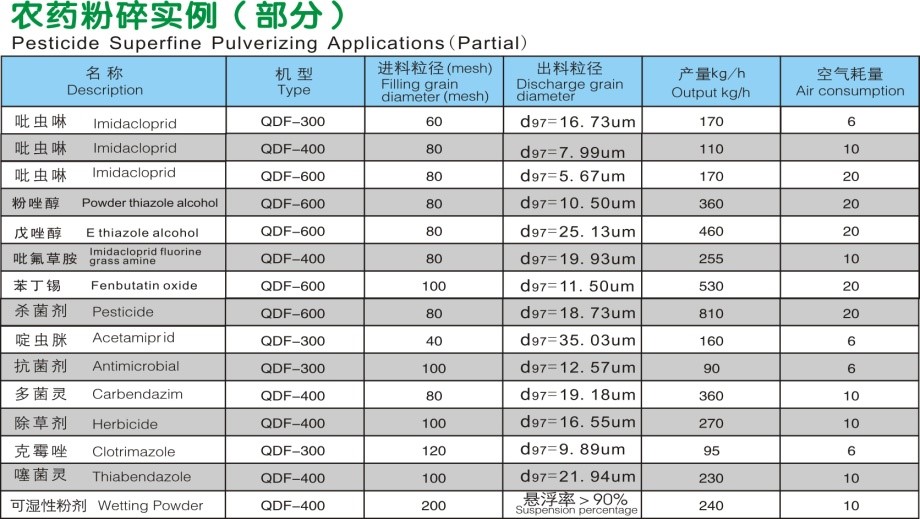

The Fluidized-bed Jet mill is actually such a device that Material fed into the main machine by a dosing feeder, the powdered material enters into the classifying area,they are impacting each other in the grinding chamber by the action of centrifugal force from high speed rotating classifier wheel and of centripetal of draft fan, the qualified powder is collected by the cyclone and bag filter,the oversized powder is continued to grinding.

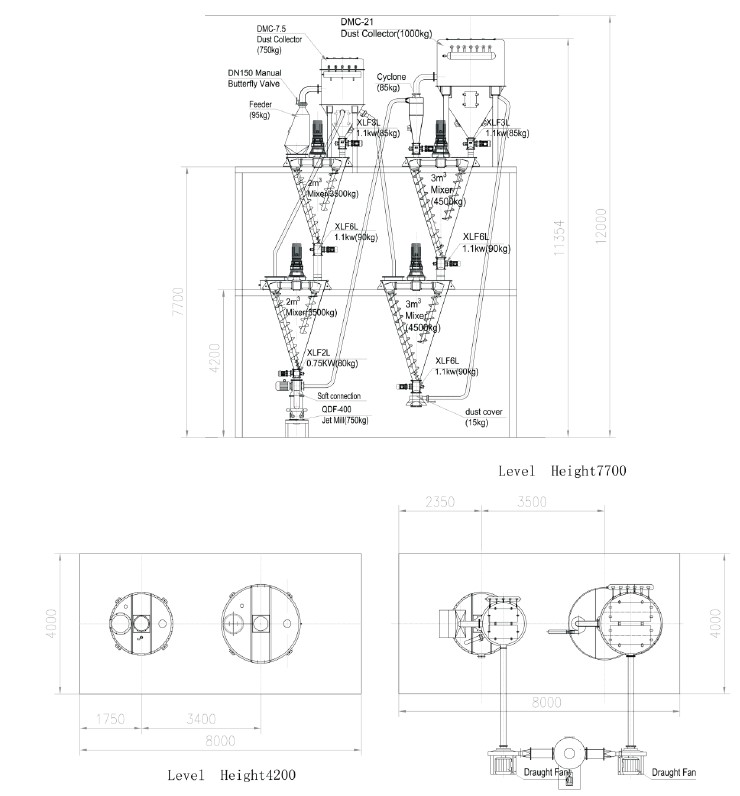

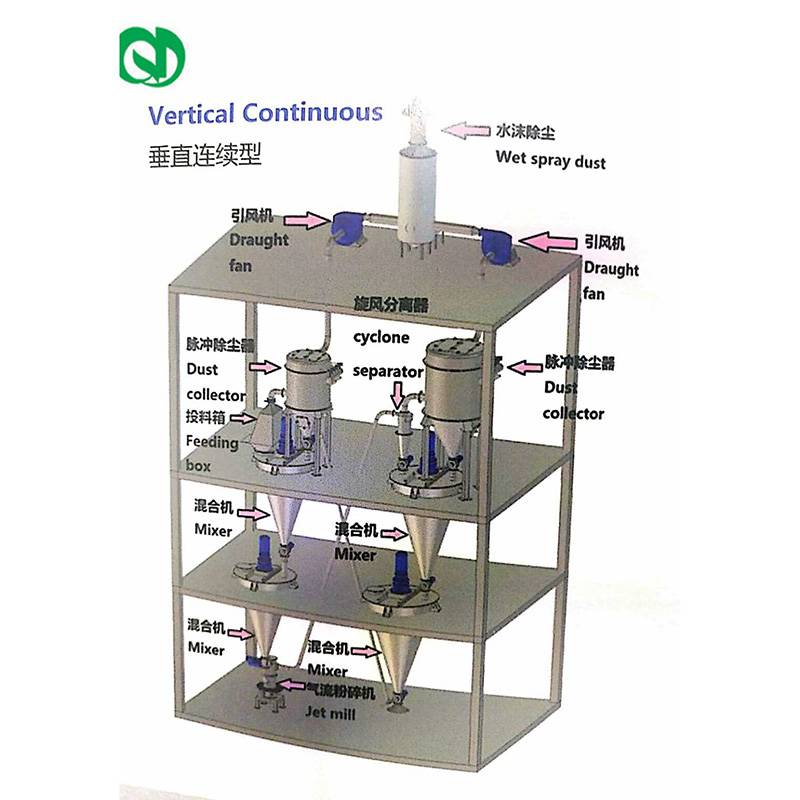

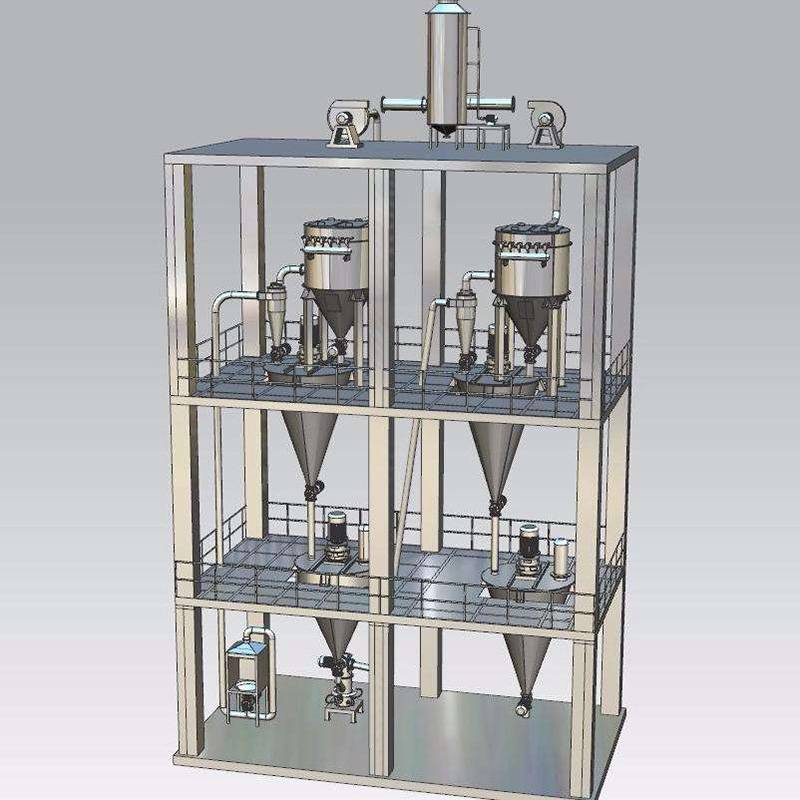

First,Raw material feed from the feeder –the material transfer to the first 3 m3mixer for premixing, and dust collector will collect dust during the feeding process, then the second 3m3 mixer store mixed material,then enter into jet mill for milling, the output particle size can be adjusted by adjusting different rotating speed of the classifier wheel,. After milling, material will transfer to the cyclone through centripetal force of draft fan and dust collector on the top of the first 4m3 mixer, then transfer to the second 4m3 mixer for mixing before package or transfer to WDG system.

PLC Control system

The system adopts intelligent touch screen control, easy operation and accurate control.

WP system is a perfect combination of jet mill technology, mixing technology and intelligent control technology. which is a satisfying product for pesticides to multi-mix and remix,Meanwhile,it meets environmental request that no dust during the whole process.

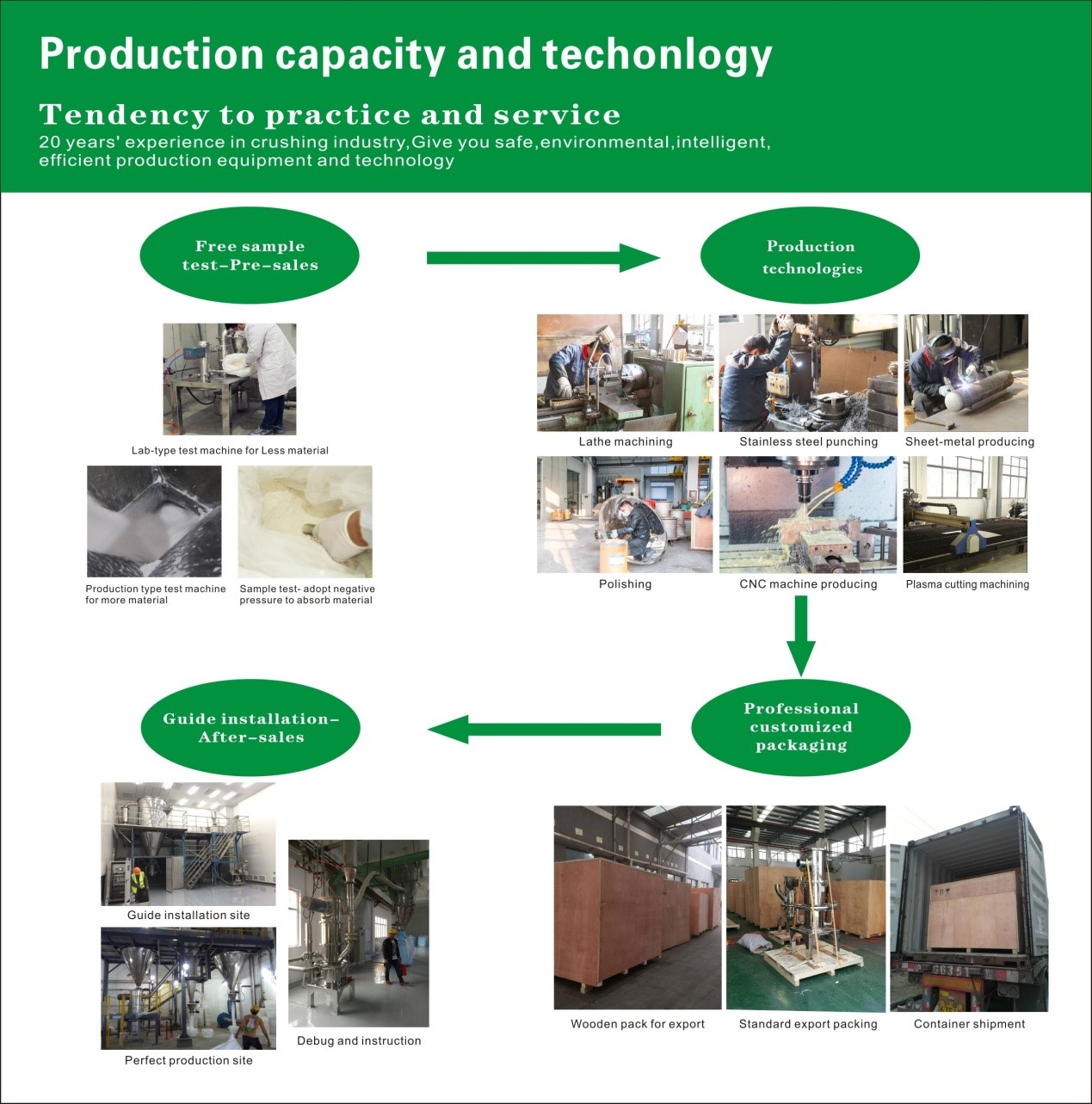

We have more than 10 technical talents who have been engaged in the system design for more than 20 years in the powder industry and have rich experience in pulverizing,mixing,drying,pelletizing,packaging,and powder conveying. in Agrochemical WP/WDG production lines,We can design the flowchart according to clients’ requirements to meet customer’s crushing requirements for various materials.

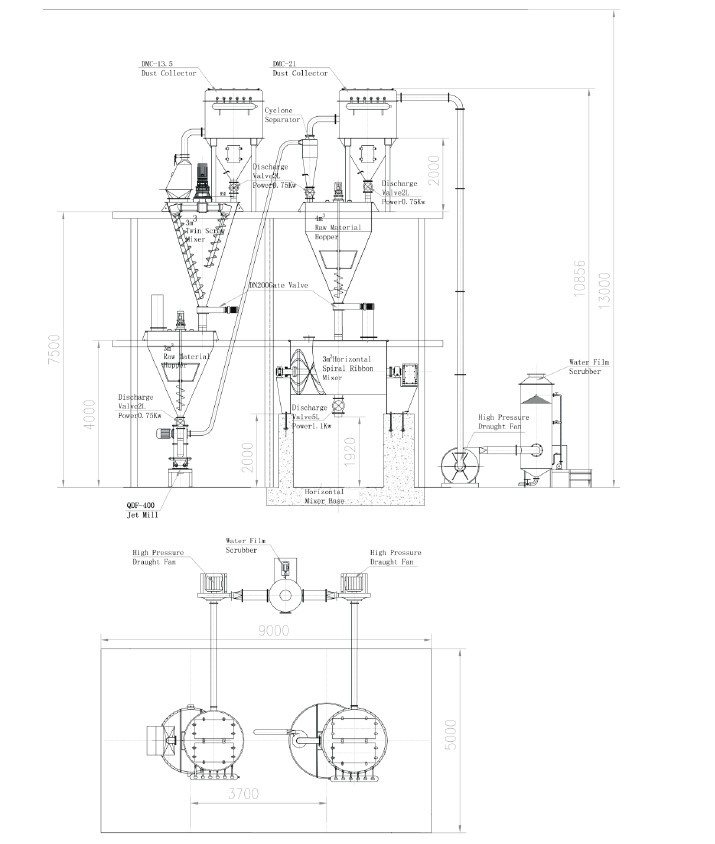

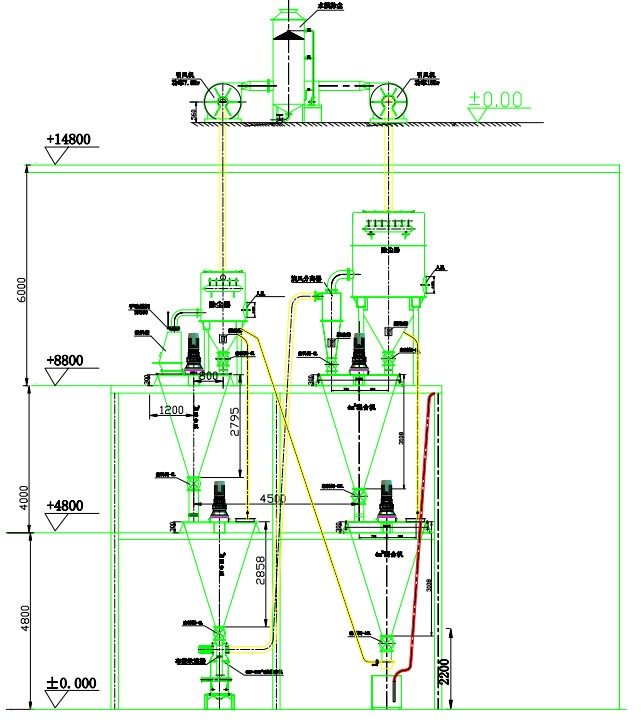

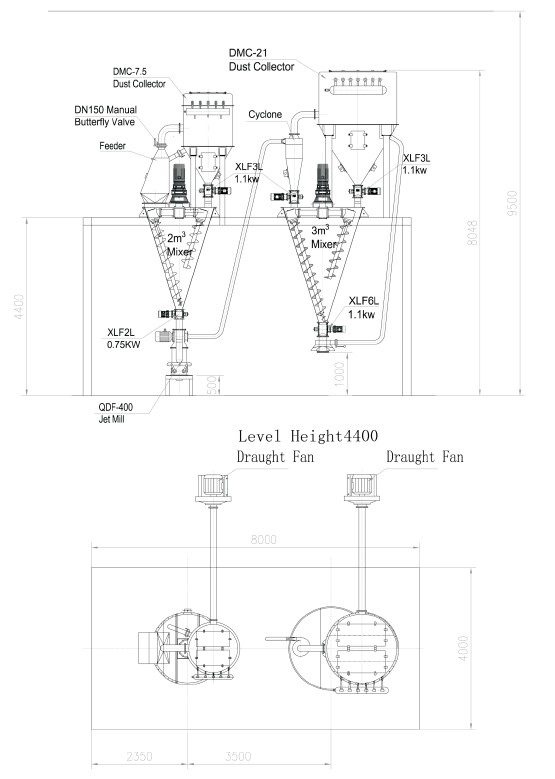

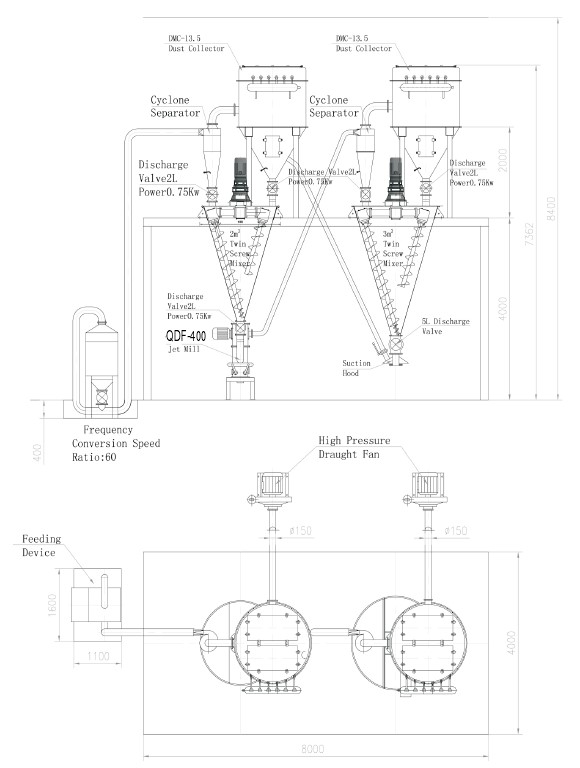

Flow chart of Fluidized-bed Jet Mill WP Line

1.The milling process is applying the fluidized-bed jet mill working principle with high efficiency, and the particle size distribution is uniform.

2.The feeding process is with the minus pressure air transportation, the exhauster is added to prevent the dust emanation.

3.Both the first and last mixing process are applying the double screw mixers or horizontal spiral ribbon blender which insure the mixing is sufficient and symmetrical.

4.The product outlet can directly connect to the auto packing machine.

5.The whole system is controlled with the remote PLC control. Convenient operation and maintenance, automatic equipment operation.

6.Low energy consumption: it can save 30%~40% energy compared with other air pneumatic pulverizers.

7. It is applicable to crushing high mixing ratio materials difficult for crush and viscous materials.

A. Continuous model,Applied to mass production (QDF-400 Recommended product for agrochemical industry)

Advantages:

1 .Pipeline connection between dust collector and finished products outlet prevent dust leaking out, realize no dust packaging and no contamination.

2.Twin screw mixer has long stirrer and screw design,which keep completely mixing material from settling down under the action of the revolution and rotation.

B. Continuous model, Applied to mass production(QDF-400 Horizontal spiral ribbon mixer design)

Advantages:

1 .Raw material hopper has mixing rod design, and the screw is enough long till the bottom to keep material flow smoothly.

2.Horizontal spiral ribbon mixer advantage: It is more convenient to make certain products which needs to add adjuvant or other chemicals at the finished product. And the mixing is much better and more accurate than the twin screw mixer. lower body height than Twin screw mixer, easy to install.

C.Continuous model,Applied to mass production(QDF-600 Twin screw mixer design)

Advantages:

Both the first and last mixing process are applying the double screw agitators which ensure the mixing is sufficient and symmetrical. The conical design keep the material flowing down smoothly.

D. Simplified model, Applied to batch production(QDF-400 Upper feeding mode)

Advantage: Cyclone separator and Dust collector: Add vibration meter to the cone part to avoid accumulation of material.

E.Simplified model, Applied to batch production (QDF-400 Bottom feeding mode)

Advantage: Cyclone separator: Add one more cyclone separator after the feeder to disperse raw material flow direction and avoid accumulation of material.

Pakistan Agriculture factory,Pesticides and Herbicides powder grinding,One set of QDF-400 WP continuous production lines,Production capacity 400kg/h ,Particle size D90:45μm

Burma Agriculture factory,Pesticides and Herbicides powder grinding,One set of QDF-400 WP simplified production lines,Production capacity 400kg/h ,Particle size D90:30μm

Pakistan Agriculture factory,Pesticides and Herbicides powder grinding,One set of QDF-400 WP continuous production lines,Production capacity 400kg/h ,Particle size D90:45μm

Egypt Agriculture factory,Pesticides and Herbicides powder grinding,One set of QDF-400 WP continuous production lines,Production capacity 400kg/h ,Particle size D90:20μm

1. Make optimal solution and layout according to clients raw material and capacity request.

2. Make booking for shipment from Kunshan Qiangdi factory to clients factory.

3. Provide installation and commissioning, training on-site for clients.

4. Provide English manual for whole line machines to clients.

5. Equipment warranty and lifelong after-sales service.

6. We can test your material in our equipment for free.

Pre-service:

Act as a good adviser and assistant of clients to enable them get rich and generous returns on their investments.

1. Introduce the product to the customer in detail, answer the question raised by customer carefully;

2. Make plans for choice according to the needs and special requirements of users in different sectors;

3. Sample testing support.

4. View our Factory.

Sale service:

1. Ensure product with high quality and pre-commissioning before delivery;

2. Deliver on time;

3. Provide full set of documents as customer’s requirements.

After-sale service:

Provide considerate services to minimize clients’ worries.

1. Engineers available to service machinery overseas.

2. Provide 12 months warranty after goods arrive.

3. Assist clients to prepare for the first construction scheme;

4. Install and debug the equipment;

5. Train the first-line operators;

6. Examine the equipment;

7. Take initiative to eliminate the troubles rapidly;

8. Provide technical support;

9. Establish long-term and friendly relationship.

1.Q: How can I trust on your quality?

Answer:

1). All of the machine be tested successfully in QiangDi workshop before shipment.

2). We supply one year warranty for all equipment and lifelong after-sales service.

3). We can test your material in our equipment before place the order, to ensure our equipment is suitable for your project.

4). Our engineers will go to your factory to install and debug the equipment, they will not be back until these equipment can produce qualified products.

2. Q: What is your superiority comparing with other suppliers?

Answer:

1). Our professional engineers can make the most suitable solution based on your kinds of raw materials, capacity and others requirement.

2). Qiangdi has many technology research and development engineers with more than 20 years experience, our R&D ability is very strong, it can develop 5-10 new technology every year.

3). We have a lot of giant customers in Agrochemical, New material, Pharmaceutical field all over the world,.

3. Q: What service can we supply for machine installation and test run? What is our warranty policy?

Answer: We send engineers to the clients’ project site and offer on-site technical instruction and supervision during the machine installation, commissioning and test run. We offer warranty of 12 months after installation or 18 months after the delivery.

- We offer lifetime service for our machine products after the delivery, and will follow up the machine status with our clients after the successful machine installation in our clients’ factories.

4. Q: How to train our staff about operation and maintenance?

Answer: We will provide every detailed technical instructive pictures to teach them for operation and maintenance. In addition, our engineers for guide assembly will teach your staff on site.

5. Q:What shipment terms you offer?

Answer: We can offer FOB, CIF, CFR etc based on your request.

6. Q:What payment terms you take?

Answer: T/T, LC at sight etc.

7. Where is your company located? How can I visit there?

Answer: Our company is located in Kunshan city, Jiangsu Province, China, it is the closest city to Shanghai. You can fly to Shanghai airport directly. We can pick you up at the airport or train station etc.

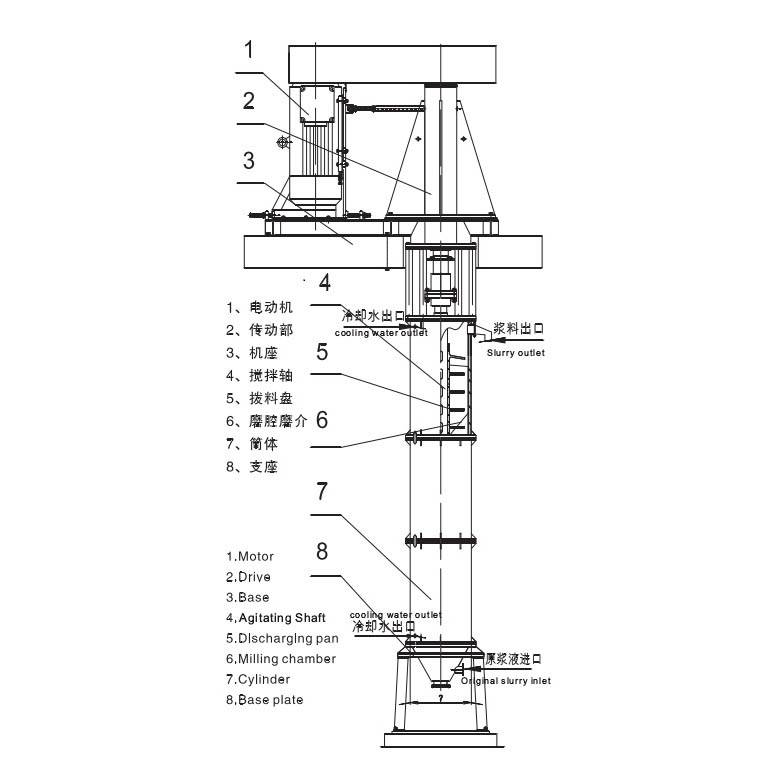

Product detail pictures:

Related Product Guide:

Our advantages are reduced prices,dynamic product sales workforce,specialized QC,solid factories,superior quality services for Factory Promotional Laboratory Jet Mill Micronizer - Jet Mill WP System–Apply to Agrochemical Field – Qiangdi , The product will supply to all over the world, such as: Egypt, Finland, Canberra, We welcome you to visit our company, factory and our showroom displayed various products that will meet your expectation, meanwhile, it is convenient to visit our website, our sales staff will try their efforts to provide you the best service. If you need more information, please do not hesitate to contact us by E-mail or telephone.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.