Factory made hot-sale Jet Power End Mill - Nitrogen Protection Jet Mill System For Special Material – Qiangdi

Factory made hot-sale Jet Power End Mill - Nitrogen Protection Jet Mill System For Special Material – Qiangdi Detail:

Nitrogen protection jet mill system –It’s a system Nitrogen as media ,under positive pressure , finishing grinding process of special products such as flammable, explosive, easily oxidized and hygroscopic materials .thereby reach different fineness powder .

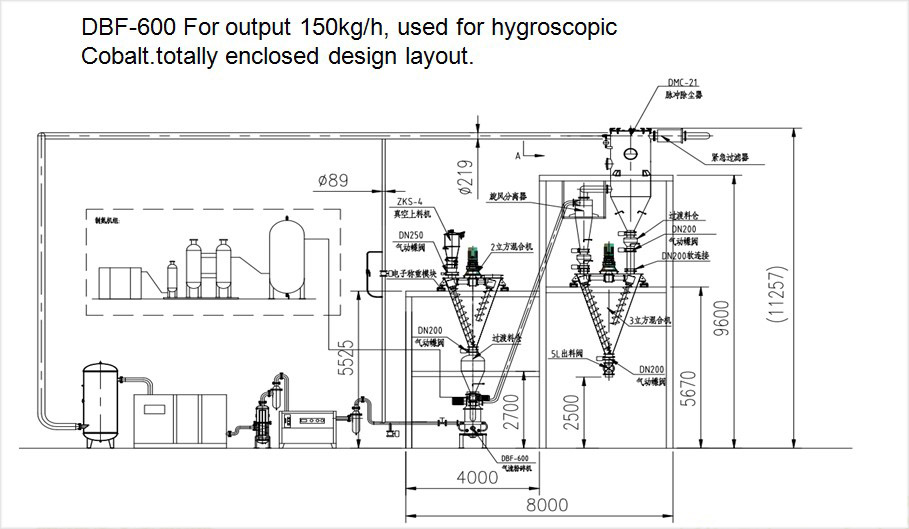

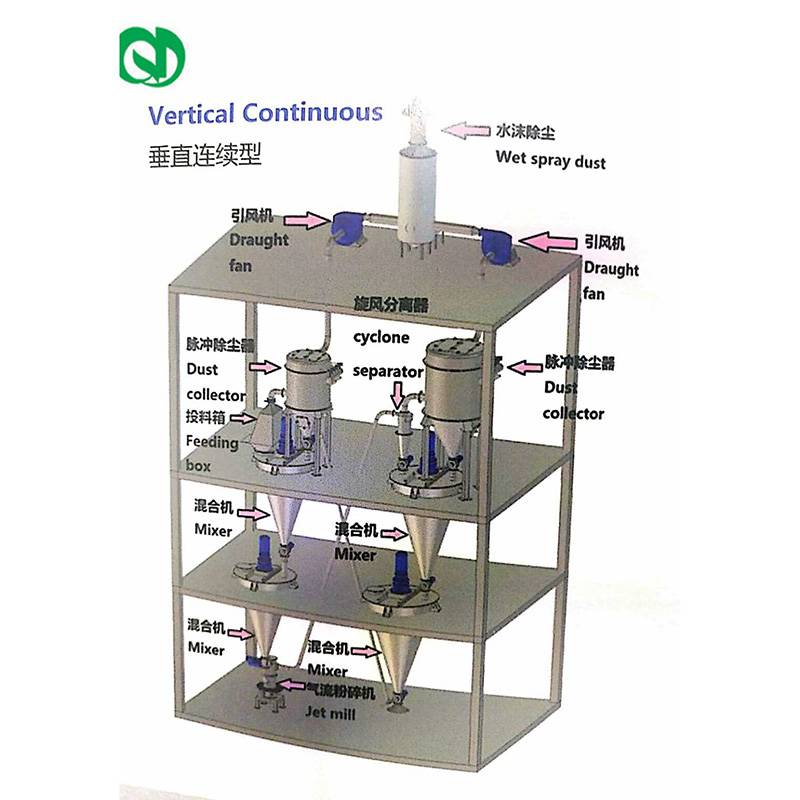

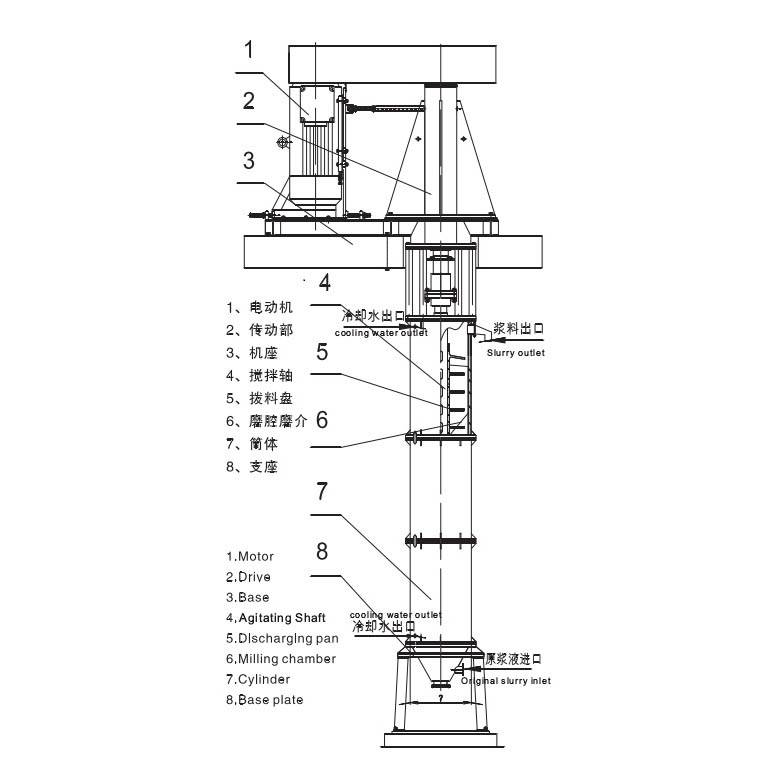

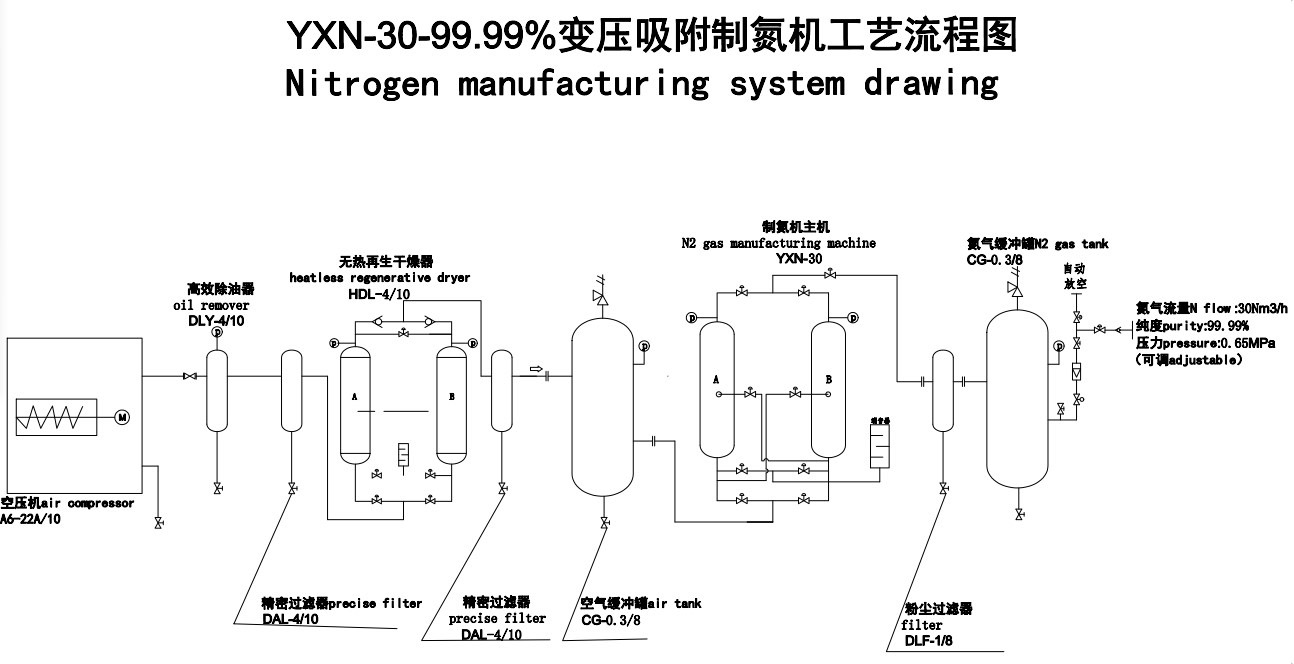

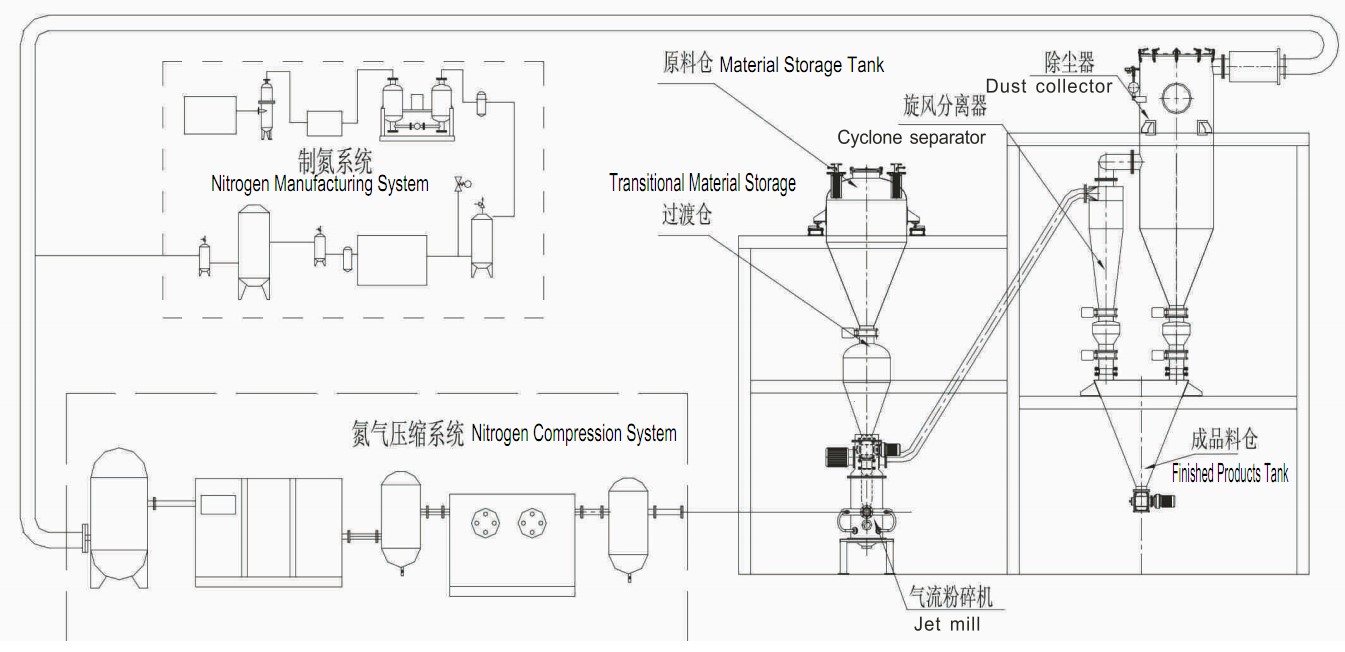

The Nitrogen protection jet mill system uses Nitrogen gas as media for pneumatic mining to perform dry-process superfine pulverization. The jet mill system mainly consists of compressor, air storage tank, material storage tank, jet mill, cyclone separator, collector and automatic controller. When the system is activated, nitrogen gas will be released into the systemto drive the air out till the whole system reaches the numerical value fixed by the oxygen detector. Then the system will automatically start the material feeding device to feed the materials evenly into the milling chamber of the jet mill. The compressed nitrogen gas is injected at a high speed into the milling chamber by means of special ultrasonic nozzle. Therefore, the materials will be ground by being accelerated, impacted and collided repeatedly in the midst Of ultrasonic injection flow. The ground materials will be brought together with upflow to the grading chamber. They cannot enter the grading wheel and will be swirled back into the milling chamber for further milling. The thinner grains will enter the grading wheel and be blasted to cyclone separator and collector whereas the nitrogen gas will return to the compressor, through Which it will be compressed for recycling.

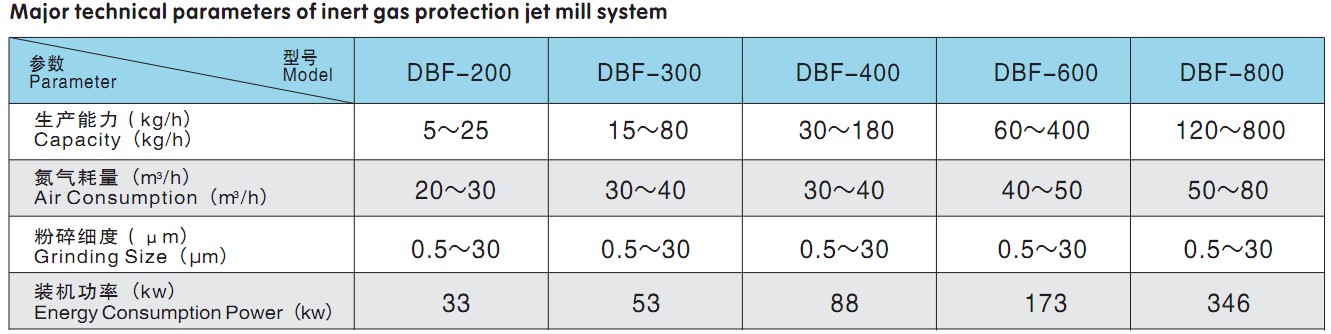

1.Suitable to pulverize flammable, explosive, easily oxidized and hygroscopic materials.

2.Operation of machine is controlled by advanced touch screen and PLC for full-auto control, It’s easy to control oxygen content.

3.Nitrogen is recycled with very low consumption. Nitrogen purity control is higher than 99%.

4.According to Material property, you can choose to use Jet mill or ultra-fine mechanical pulverizer.

5.It’s widely used in Sulphur, Cobalt, nickel, boron oxide and hygroscopic cosmetics so on.

6. Weighing control system, high precision, optional, high product stability.

Explosion-proof design for nitrogen circulation system to meet the ultra-fine grinding processing requirements of flammable and explosive oxide materials.

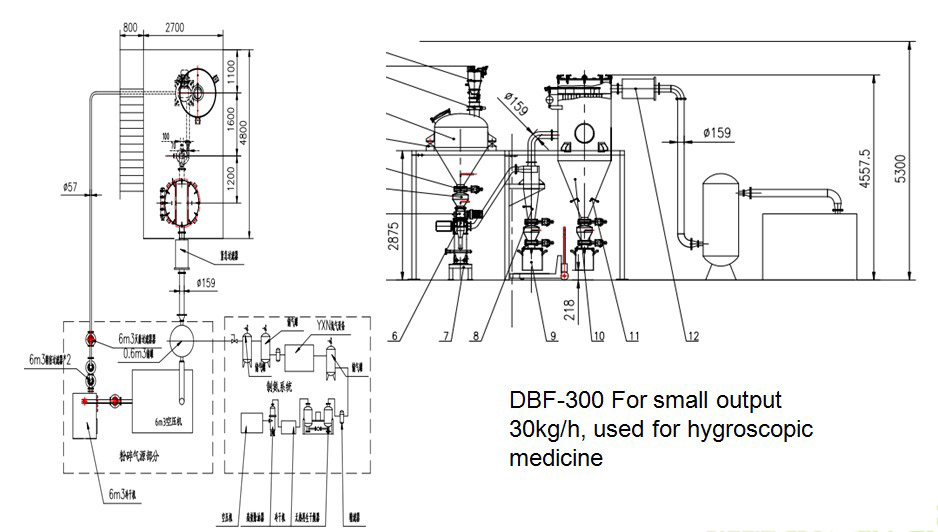

The flow chart is standard milling processing,and can be adjusted for customers.There are three parts for the whole system:Nitrogen manufacturing system,Nitrogen compression system,enclosed grinding system.

Applicated in Medicines(Chinese customer)

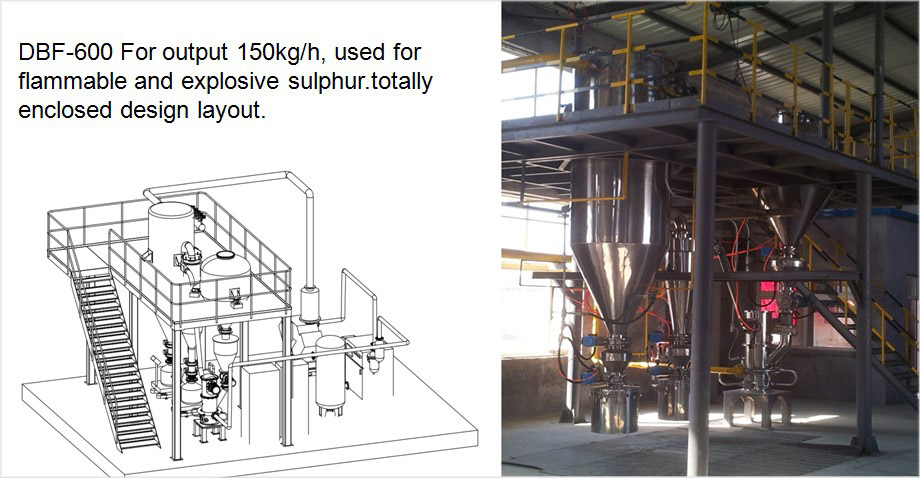

Applicated in Sulphur

DBF-400 With pasting Ceramics and PU .because of its high hardness and used for battery industry,Moreover,it is a hygroscopic material,So we use NPS for grinding this material.

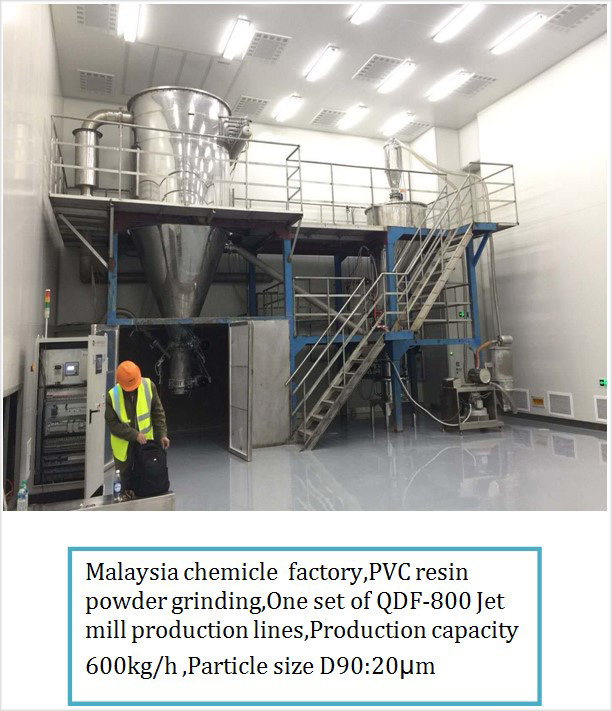

Hongkong chemicle factory,Poly-Si powder grinding for battery,One set of DBF-400 Nitrogen protection Jet mill production lines,Production capacity 200kg/h ,Particle size D90:15μm

◆ Our products have a good market in the whole China,

Whatever In pharmaceutical,Agrochemical,New Material,Battery&Electron,Coating&Pigments industries.

◆ We export our products to worldwide: America, Australia, Africa and Southeast Asia and Middle-east Countries, such as Pakistan, Korea, Vietnam, India, Burma,Cambodia,Indonesia,Malaysia,Singapore,Japan,Thailand,Egypt,Ukraine,Russia,etc. Mainly in Agriculture Field.

Product detail pictures:

Related Product Guide:

We believe that prolonged expression partnership is really a result of top of the range, value added support, rich encounter and personal contact for Factory made hot-sale Jet Power End Mill - Nitrogen Protection Jet Mill System For Special Material – Qiangdi , The product will supply to all over the world, such as: Kenya, Lithuania, Mexico, With the aim of "compete with good quality and develop with creativity" and the service principle of "take customers' demand as orientation", we will earnestly provide qualified products and solutions and good service for domestic and international customers.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.