Factory directly Jet Mill Micronizer India - GMP FDA Fluidized-bed Jet Mill – Qiangdi

Factory directly Jet Mill Micronizer India - GMP FDA Fluidized-bed Jet Mill – Qiangdi Detail:

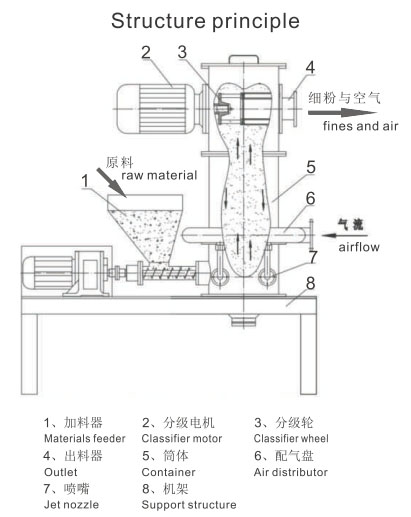

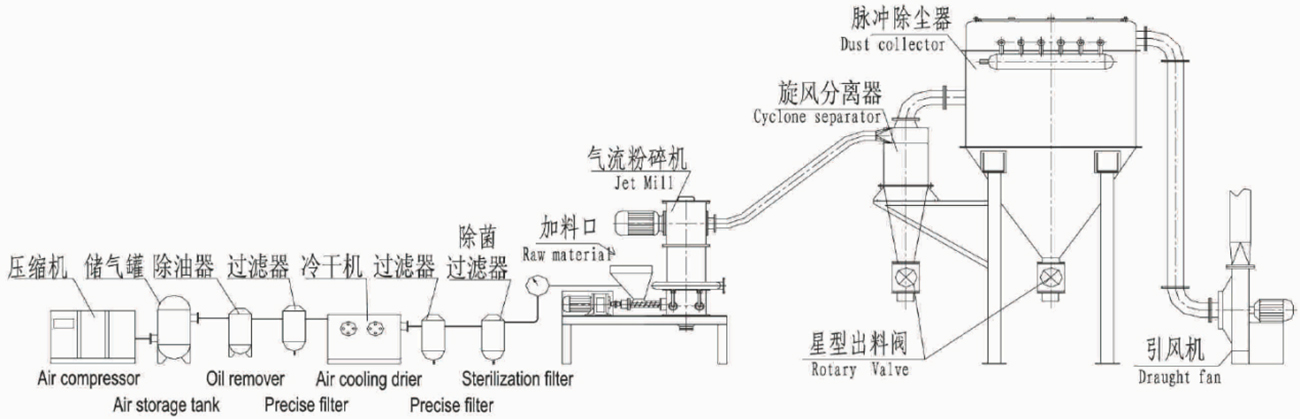

Jet mill structure drawing- under the action of centrifugal force of classifier wheel and centripetal force of draft fan,material come into being fluid-bed in the inner of jet mill.thereby getting different fineness powder .

The Product is a fluidized bed pulverizer with the compression air as the crushing medium. The mill body is divided into 3 sections, namely the crushing area, transmission area and the grading area. The Grading Area is provided with the grading wheel, and the speed can be adjusted by the converter. The crushing room is composed of the crushing nozzle, feeder, etc. The ring sir supply disc outside the crushing canister is connected with the crushing nozzle

The material enters the crushing room through the material feeder. The compression air nozzles into the crushing room in high speed through the specially equipped four crushing nozzles. The material gains acceleration in the ultrasonic jetting flow and repeatedly impact and collide at the central converging point of the crushing room until it is crushed. The crushed material enters the grading room with the upflow. Because the grading wheels spin at high speed, when the material ascends, the particles are under the centrifugal force created from the grading rotors as well as the centripetal force created from the viscosity of the airflow. When the particles is under the centrifugal force larger than the centripetal force, the coarse particles with larger diameter than the required grading particles will not enter the inner chamber of the grading wheel and will return to the crushing room to be crushed. The fine particles that comply with the diameter of the required grading particles will enter the grading wheel and flow into the cyclone separator of the inner chamber of the grading wheel with the airflow and get collected by the collector. The filtered air is released from the air intaker after the filter bag treatment.

1.The particles can reach 0.5-10 micron thanks to extremely high airflow speed and tremendous impact force.

2. Classifying devices are available inside the pulverizer, through which the coarse particles from the processing materials can be cyclically pulverized to produce finished products with uniform grain fineness and small range of particle diameters.

3.Product design, material selection completely in accordance with GMP/FDA standard requirements.No pollution to material in the milling process.

4.The airflow is extremely pure with filtering process. Compact internal structure to perform the closed circuit milling. From raw materials to continuous production of finished products, the pulverization requires very short time but yields higher efficiency and continuous operation.

5.The equipment structure is simple, the inner and outer highly polished,no dead angle, easy to clean.

6.Low wear: Because the crushing effect is caused by the impact and collision of particles, the high-speed particles seldom hit the wall. It is applicable to crushing the material below Moh’s Scale 9.

7.Relevant industry inspections and certifications ,such as FAT.SAT.DQ.OQ.IQ.PQ.

1.Loading hopper with seal cover to avoid products polluted.

2.All motors with cap to be protected and keep products clean. Professional design.

3.All machine material contact with products must be stainless steel ,no dead angle and no pollution.

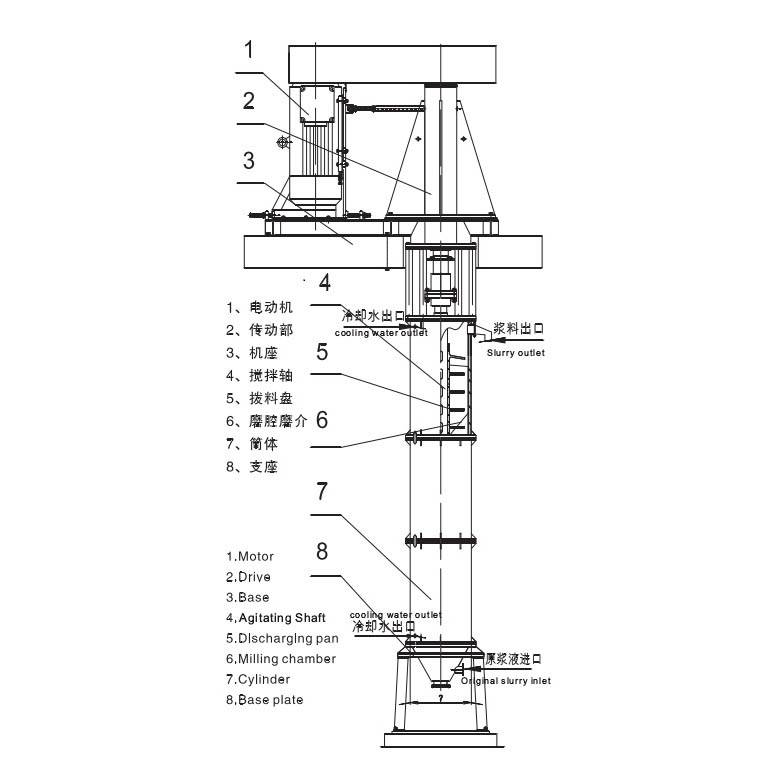

The pneumatic pulverizer is composed of the air compressor, oil remorer,gas tank, freeze dryer, air filter, fluidized bed pneumatic pulverizer, cyclone separator, collector, air intaker and others.

PLC Control system

The system adopts intelligent touch screen control, easy operation and accurate control. This system adopts advanced PLC + touch screen control mode, the touch screen is the operation terminal of this system, thus, it is very important.to accurately grasp all keys’ function on the touch screen to ensure correct operation of this system.

Medical Intermediate

→MEFENAMIC ACID raw material from 60Mesh ground to be D90<5.56um

→ECONAZOLE NITRATE raw material from 60Mesh ground to be D90<6um

Food Powder

→MANGO POWDER raw material from 70Mesh ground to be D90<10um (suitable for heat sensitive food.)

→TEA POWDER raw material from 50Mesh ground to be D90<10um

Mainly used in Pharmaceutical, Food, and Cosmetics Industry.

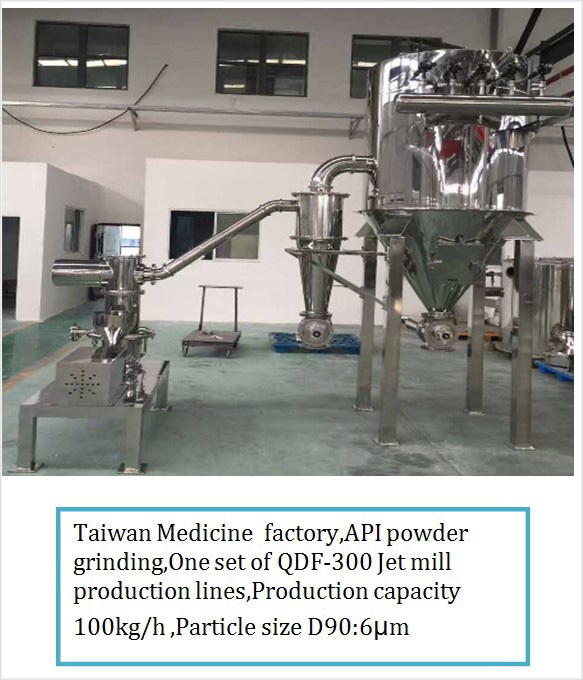

Product detail pictures:

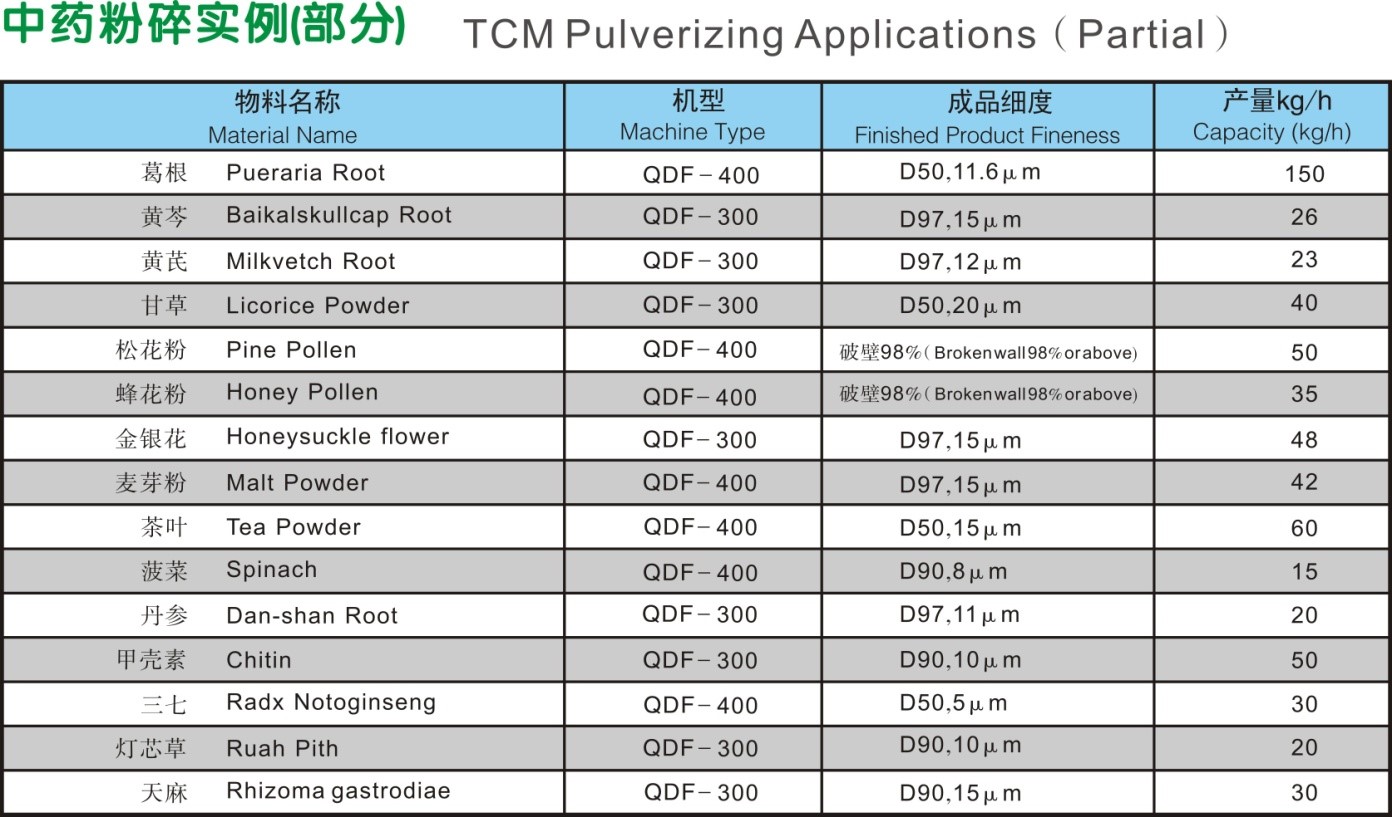

Related Product Guide:

In the past few years, our company absorbed and digested advanced technologies both at home and abroad. Meanwhile, our company staffs a team of experts devoted to the development of Factory directly Jet Mill Micronizer India - GMP FDA Fluidized-bed Jet Mill – Qiangdi , The product will supply to all over the world, such as: Manchester, Buenos Aires, Bolivia, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which will be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we are going to continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

This supplier offers high quality but low price products, it is really a nice manufacturer and business partner.