Chinese Professional Jet Mill - QDF-400 WP Continuous Production System Of Jet Mill For 400kg – Qiangdi

Chinese Professional Jet Mill - QDF-400 WP Continuous Production System Of Jet Mill For 400kg – Qiangdi Detail:

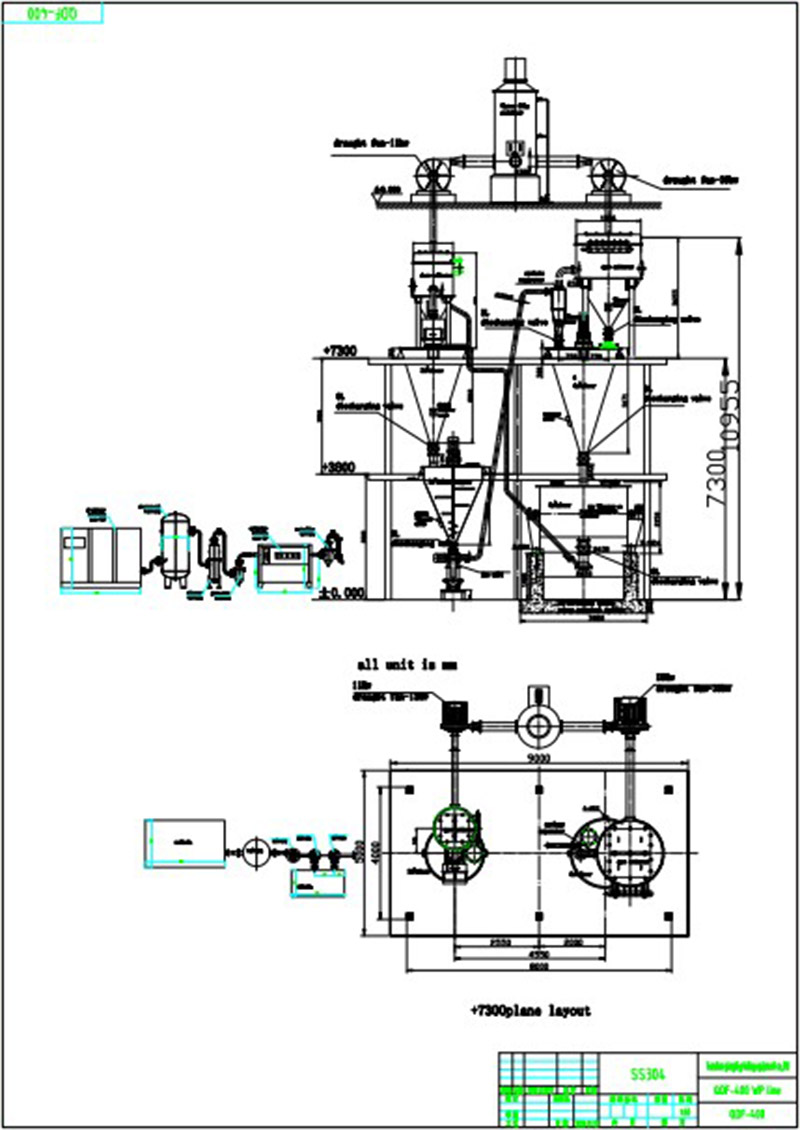

The Most popular WP line in Pakistan-QDF-400 continuous production system as below Flow diagram and photo

First,Raw material feed from the feeder –the material transfer to the first 3 m3mixer for premixing, and dust collector will collect dust during the feeding process, then the 3m3 hopper store mixed material,then enter into jet mill for milling, the output particle size can be adjusted by adjusting different rotating speed of the classifier wheel,. After milling, material will transfer to the cyclone through centripetal force of draft fan and dust collector on the top of the first 4m3 mixer, then transfer to the second 4m3 horizontal ribbon mixer for mixing before package or transfer to WDG system.

1.The milling process is applying the fluidized-bed jet mill working principle with high efficiency, and the particle size distribution is uniform.

2.The feeding process is with the minus pressure air transportation, the exhauster is added to prevent the dust emanation.

3.Both the first and last mixing process are applying the double screw mixers or horizontal spiral ribbon blender which insure the mixing is sufficient and symmetrical.

4.The product outlet can directly connect to the auto packing machine.

5.The whole system is controlled with the remote PLC control. Convenient operation and maintenance, automatic equipment operation.

6.Low energy consumption: it can save 30%~40% energy compared with other air pneumatic pulverizers.

7. It is applicable to crushing high mixing ratio materials difficult for crush and viscous materials.

Air source system- air compressor, oil remover,air storage tank,air freeze dryer, precise filter.

WorkingPrinciple

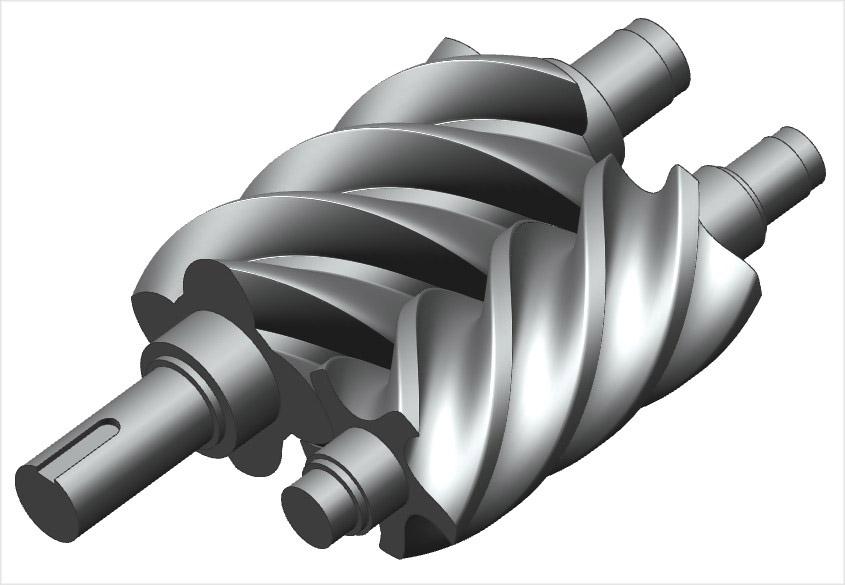

Compressor is used to compress air, single-stage, oil-injected and driven by motor, which includes air end, motor, oil/gas separator, oil cooler, air cooler, fan (for air-cooled type only), moisture trap, electric control cabinet, gas pipeline, oil pipeline and water pipeline (for water-cooled type only), regulation system.There is a pair of conjugated rotors inside casing. Male rotor has 4 teeth, female rotor has 6 teeth. Female rotor is followed by male rotor at high-speed. With teeth displacement less between 2 rotors, air from inlet filter and lubricated oil from casing are gradually compressed with high pressure. When teeth displacement is straight to outlet port, compressed air/oil mixture are flowing from the outlet port, then flowing into oil/gas separator to separate oil from air. Next, air flow through minimum pressure valve, air cooler and moisture trap, finally to air delivery pipeline. Separated oil is dropping at the bottom of separator, then flow into oil cooler, oil filter and finally to air end for recycle use at the result of differential pressure.

Working Principle

Hot and humid and cold air to enter the first pre-cooled heat exchangers (the evaporator out of the cold compressed air to heat exchange) in order to reduce the load on the evaporator, while heating the compressed air discharged from the cold, away from saturation. Then enters the evaporator was further cooled to 12 ℃ below, re-entering the separator will be precipitated in the cooling process of water have been isolated, mountain sub-Shui device discharges. Out of the dry cold air on the heat emitted by the pre-cooling heat exchanger.

Working Principle

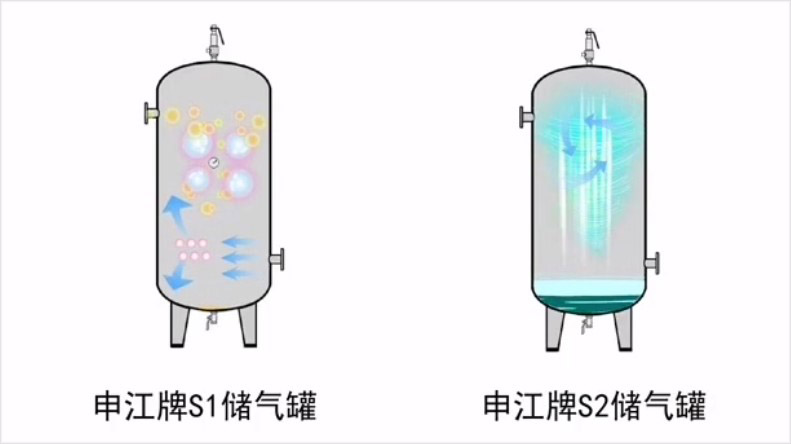

air storage tank (pressure vessel), also known as compressed air storage tank, is a pressure vessel specially used for storing compressed air. It is mainly used for storing gas buffer, and plays the role of stabilizing system pressure, so as to avoid frequent loading and unloading of air compressor and removing most liquid water.The gas storage tank is generally composed of cylinder body, head, flange, nozzles, sealing elements and supports and other parts and components.In addition, also equipped with safety valve, pressure gauge, drain valve and other accessories to complete the role of different production processes.

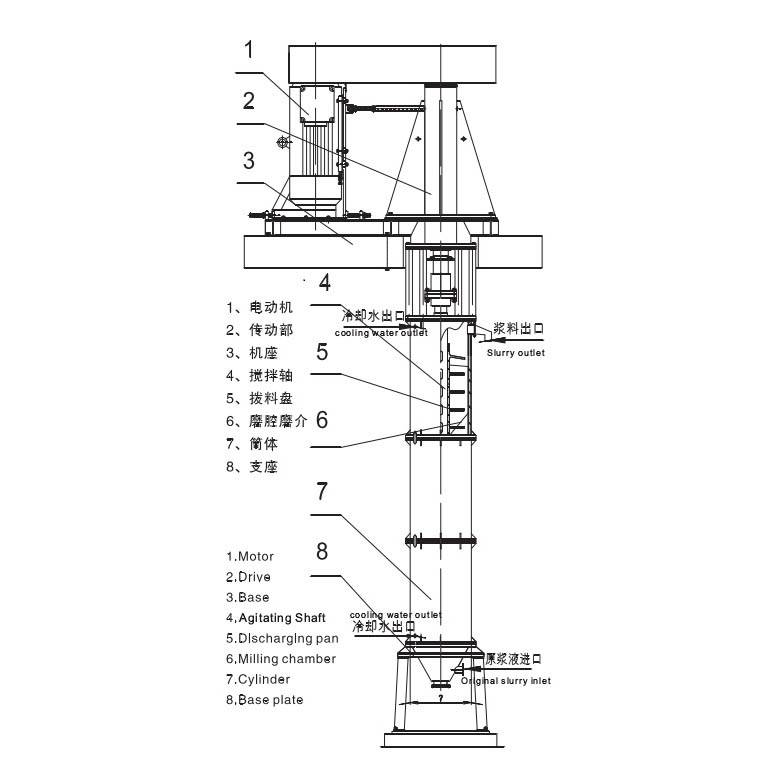

The Product is a fluidized bed pulverizer with the compression air as the crushing medium. The mill body is divided into 3 sections, namely the crushing area, transmission area and the grading area. The Grading Area is provided with the grading wheel, and the speed can be adjusted by the converter. The crushing room is composed of the crushing nozzle, feeder, etc. The ring air supply disc outside the crushing canister is connected with the crushing nozzle.

Jet mill- under the action of centrifugal force of classifier wheel and centripetal force of draft fan,material come into being fluid-bed in the inner of jet mill.thereby getting different fineness powder .

PLC Control system- The system adopts intelligent touch screen control, easy operation and accurate control. This system adopts advanced PLC + touch screen control mode, the touch screen is the operation terminal of this system, thus, it is very important.to accurately grasp all keys’ function on the touch screen to ensure correct operation of this system.

Upper Feeder-Flexibly connected to dust collector to avoid dust leaking,available for continous feeding .

Cyclone separator and dust collector –Products collecting and dust collecting disperse raw material flow direction and avoid accumulation of material. Ensure the dust recycling in the process of production to meet the environmental protection requirement of clean production and exhaust emission.

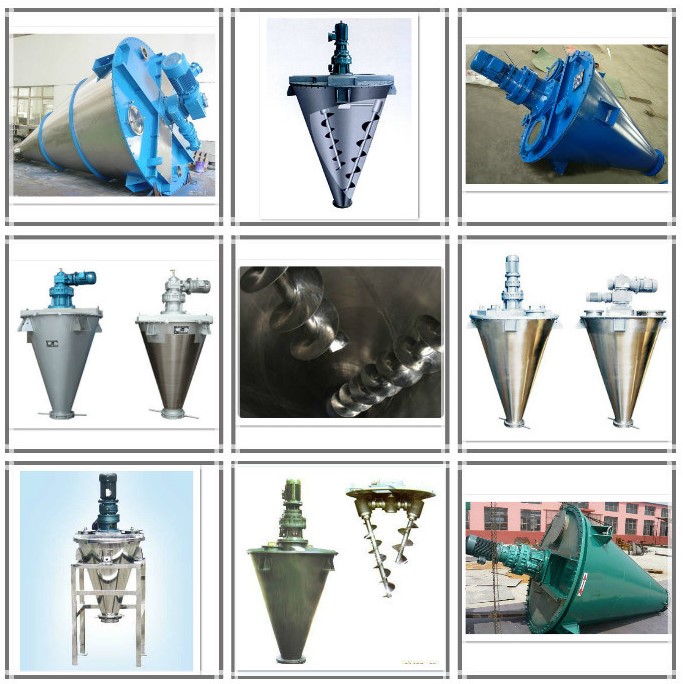

Twin screw mixer -has long stirrer and screw design,which keep completely mixing material from settling down under the action of the revolution and rotation.

Working principle

Twin screw mixer integrates powder, granule and liquid mixing. The rotation of twin screw mixer is completed by a set of motors and cycloid reducers. With asymmetric mixing by two screws, the stirring range will be expanded and stirring speed will accelerate. The mixing machine is promoted by two asymmetric spirals of the rapid rotation, forming two non-symmetrical spiral columns that flow upward from the cylinder wall. Turning arm driven by spiral orbit, makes the spiral material of different level into the stud in the envelope, dislocation part of the material being promoted, the other part of the material being thrown screw, so as to achieve full circle bearing materials constantly updated.

Horizontal spiral ribbon mixer- It is more convenient to make certain products which needs to add adjuvant or other chemicals at the finished product. And the mixing is much better and more accurate than the twin screw mixer. lower body height than Twin screw mixer, easy to install.

Working principle:

Horizontal double ribbon mixer consist of horizontal U-shaped tank, top cover with (or without) openings, single shaft equipped with double layers ribbon mixing agitator, transmission unit, support frame, sealing element, discharge structure and so on. Ribbon blades are always two layers. Outer layer ribbon make materials get together from two ends to center and inner layer ribbon make materials spread from center to two ends. Materials forms vortex during repeatedly movement and homogeneous mixing are achieved.

Draft fan- Make the whole WP system under negative pressure by centrifugal force of draft fan,thereby drive the material to crush and release exhaust gas from the grinding system.

Water scrubber- lower than 0.5um powder come into water scrubber and absorbed by the water film layer,dumped along with the bottom cone of the water flow.to avoid dust polluting environment.

Dust-containing gas is introduced along the tangential direction from the lower part of the cylinder and rotates up. Dust particles are separated by centrifugal force and thrown to the inner wall of the cylinder. They are adsorbed by the water film layer flowing in the inner wall of the cylinder and discharged through the dust outlet along with the bottom cone of the water flow.The water film is formed by several nozzles arranged on the upper part of the cylinder to spray water tangentially to the wall of the device.In this way, the inner wall of the cylinder is always covered with a very thin water film rotating downward to achieve the purpose of improving the dust removal effect.

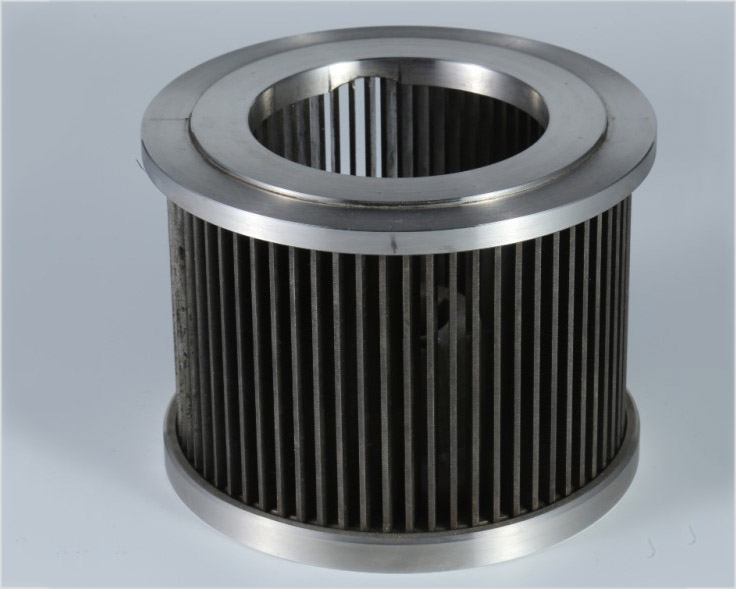

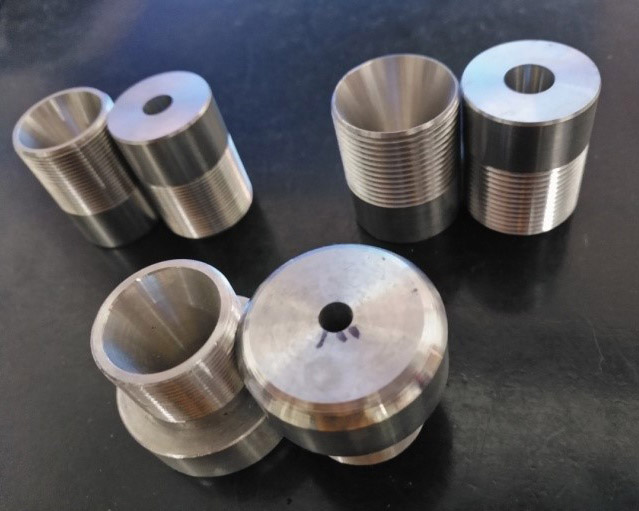

Classifier wheel

Magnetic valve

Nozzle

Discharge valve

Outlet

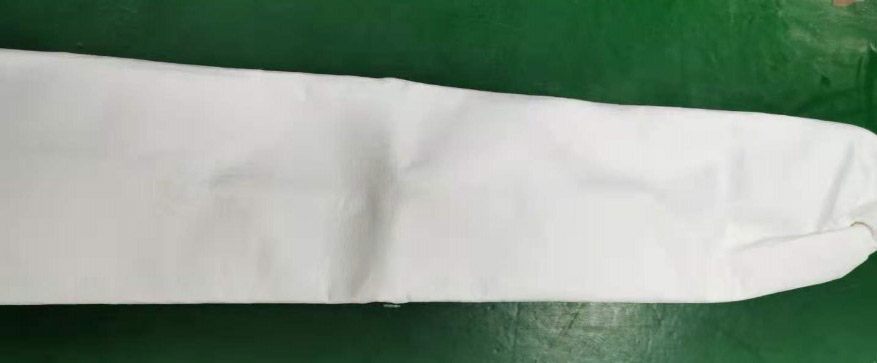

Filter Bag

Product detail pictures:

Related Product Guide:

The corporate keeps towards the operation concept "scientific administration, superior quality and performance primacy, client supreme for Chinese Professional Jet Mill - QDF-400 WP Continuous Production System Of Jet Mill For 400kg – Qiangdi , The product will supply to all over the world, such as: Iceland, Latvia, Switzerland, We also have good cooperation relationships with many good manufacturers so that we can provide almost all of auto parts and after-sales service with high quality standard,lower price level and warmly service to meet demands of customers from different fields and different area.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!