China Gold Supplier for Home Built Jet Mill - Lab-use Disc-type jet mill QDB-50 QDB-100 QDB-150 – Qiangdi

China Gold Supplier for Home Built Jet Mill - Lab-use Disc-type jet mill QDB-50 QDB-100 QDB-150 – Qiangdi Detail:

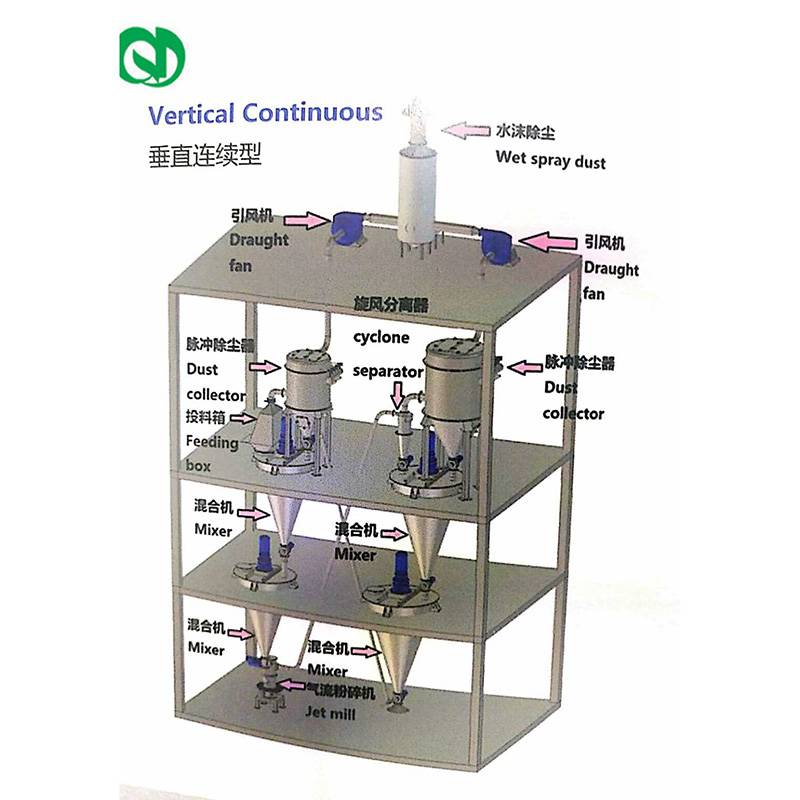

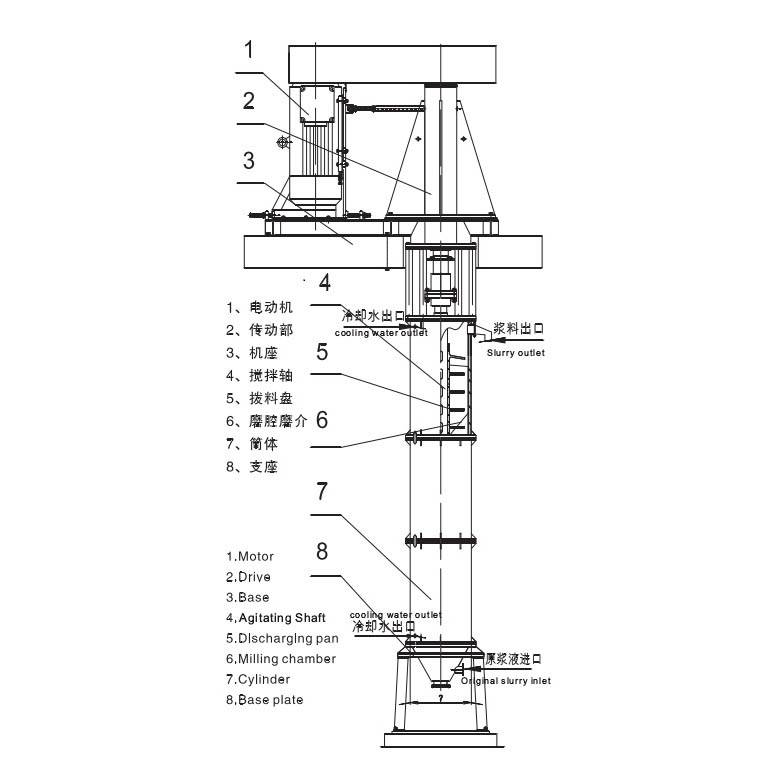

Jet Mill used in Lab, whose principle is : Driven by compressed air through feeding injectors,raw material is accelerated to ultrasonic speed and injected into milling chamber in tangential direction, collided and grinded into particle. The particle size can be controlled by adjusting longitudinal depth, milling pressure and material feeding speed. Disc type Jet Mill do good performance to gummy materials.

1.Small batch production demand of lab,using the desktop design.

2.The production capacity is 50-300g batch, what’s more, it can reach to 300-1000g batch, even 3-5kg batch while changing the design of the collection device. the flexible design completely avoids different machine models usage.

3.Adopt simple bag collecting mode to save cost.

4.Several times grindings to achieve fineness requirement.

APPLICATON SCOPE

It is widely applied to superfine pulverizing for nonmetallic ores, chemical metallurgy, western medicines, traditional Chinese medicine, agricultural chemical and ceramics, fit to be used in Lab.

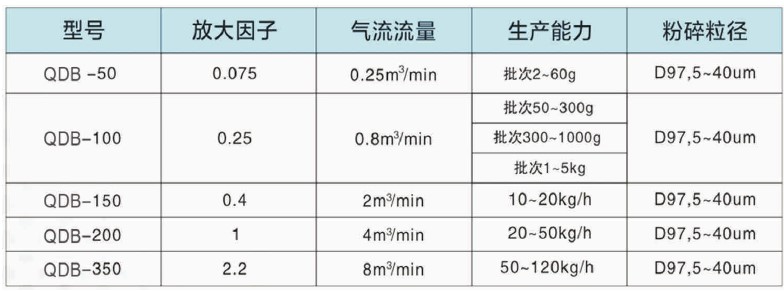

| model | Amplification factor | Air flow rate | Capacity | Grinding Size |

| QDB -50 | 0.075 | 0.25m/min | batch 2~60g | D97,5~40um |

| QDB-100 | 0.25 | 0.8m/min | batch 50~300g | D97,5~40um |

| batch 300~1000g | ||||

| batch 1~5kg | ||||

| QDB-150 | 0.4 | 2mmin | 10~20kg/h | D97,5~4Oum |

| QDB-200 | 1 | 4m%min | 20~50kg/h | D97,5~4Oum |

| QDB-350 | 2.2 | 8m3min | 50~120kg/h | D97,5~40um |

Product detail pictures:

Related Product Guide:

We insist on offering premium quality manufacturing with superior business concept, honest product sales as well as finest and fast assistance. it will bring you not only the good quality product or service and huge profit, but the most significant is to occupy the endless market for China Gold Supplier for Home Built Jet Mill - Lab-use Disc-type jet mill QDB-50 QDB-100 QDB-150 – Qiangdi , The product will supply to all over the world, such as: Cancun, Tunisia, United States, Providing Quality Items, Excellent Service, Competitive Prices and Prompt Delivery. Our products and solutions are selling well both in domestic and foreign markets. Our company is trying to be one important suppliers in China.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!